Are you only looking at the sticker price when considering excavator ownership? You shouldn’t be. The numbers tell a different story entirely. Mini excavators start from AUD 30,580, mid-size models typically sit between AUD 137,609 to AUD 275,218, and large excavators easily push beyond AUD 764,495.

Here’s what most buyers don’t realise: these initial excavator prices represent just the tip of the iceberg. Age, condition, operating hours, and brand reputation all dramatically affect your final investment. That well-maintained used excavator might look like a bargain upfront, but excavation service costs—ranging from AUD 611 to AUD 2,293 depending on project complexity—can quickly turn your “smart purchase” into an expensive lesson.

The big question you’ll need to answer is: Are you prepared for the operational costs that dealers conveniently forget to mention during the sales pitch?

This guide cuts through the marketing fluff surrounding excavator expenses in 2025, exposing the hidden costs that can make or break your project budget. Whether you’re eyeing a compact mini digger for residential work or a massive earthmover for commercial projects, you’ll discover exactly what to budget for beyond that initial purchase price.

How Much Does an Excavator Cost in 2025?

The excavator market presents a broad spectrum of investment options, each tailored to specific operational requirements. Smart buyers examine both new and used machines across all size categories before making their decision.

Price Breakdown by Size and Type

Your excavator investment depends heavily on the machine’s size and capabilities:

- Mini Excavators (1-6 tons): Ideal for residential projects and confined spaces, these compact machines range from AUD 30,580 to AUD 168,189

- Small/Compact Excavators (6-10 tons): Perfect for suburban construction site work, priced between AUD 76,450 and AUD 275,218

- Medium Excavators (11-25 tons): The workhorses of commercial construction projects, costing AUD 137,609 to AUD 458,697

- Large Excavators (26-45 tons): Built for heavy-duty applications, priced from AUD 305,798 to AUD 764,495

- Extra-Large Excavators (45+ tons): Mining industry specialists, ranging from AUD 611,596 to over AUD 2.29 million

Note: These figures represent the current Australian market and can fluctuate based on dealer location and seasonal demand.

Used Excavator Pricing Factors

The pre-owned market operates on different principles entirely. Age and operating hours create the foundation of value assessment. A 3-5 year old excavator typically retains 50-70% of its original purchase price. Machines logging fewer than 5,000 hours command premium resale values compared to heavily worked equipment.

Maintenance records tell the real story of a machine’s condition. Well-documented service history can boost a machine’s value by 10-15%, demonstrating responsible ownership and potentially reducing your future repair expenses.

Brand reputation carries significant weight in pricing decisions. Established manufacturers like Caterpillar, Komatsu, and Hitachi maintain stronger resale values thanks to proven durability and readily available parts. This reputation translates directly into better long-term investment protection.

What Affects New Excavator Prices

New machine pricing follows predictable patterns based on several key variables.

Operating weight drives the primary cost structure. Heavy machinery naturally commands higher prices. Engine specifications add another layer of expense, with each additional 10 horsepower potentially increasing your investment by approximately AUD 3,058.

Advanced technology features represent a substantial price consideration. GPS systems, telematics, and automated grade control can add AUD 15,290 to AUD 76,450 to your base price. However, these systems often deliver improved efficiency and precision that justifies the additional expense.

Emission compliance requirements now add 5-10% to base pricing, reflecting the industry’s shift toward cleaner operation standards. This regulatory requirement affects all new purchases regardless of size category.

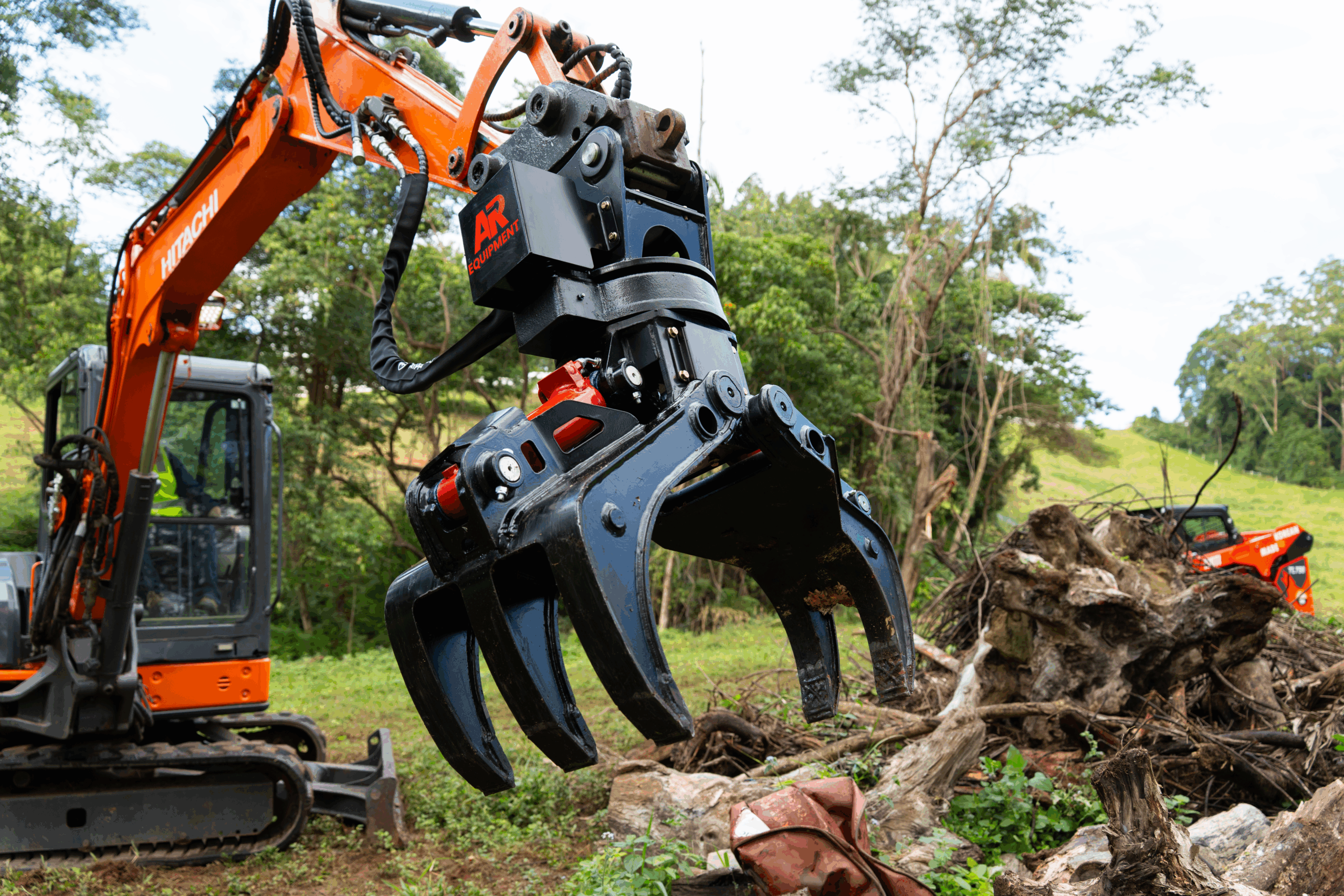

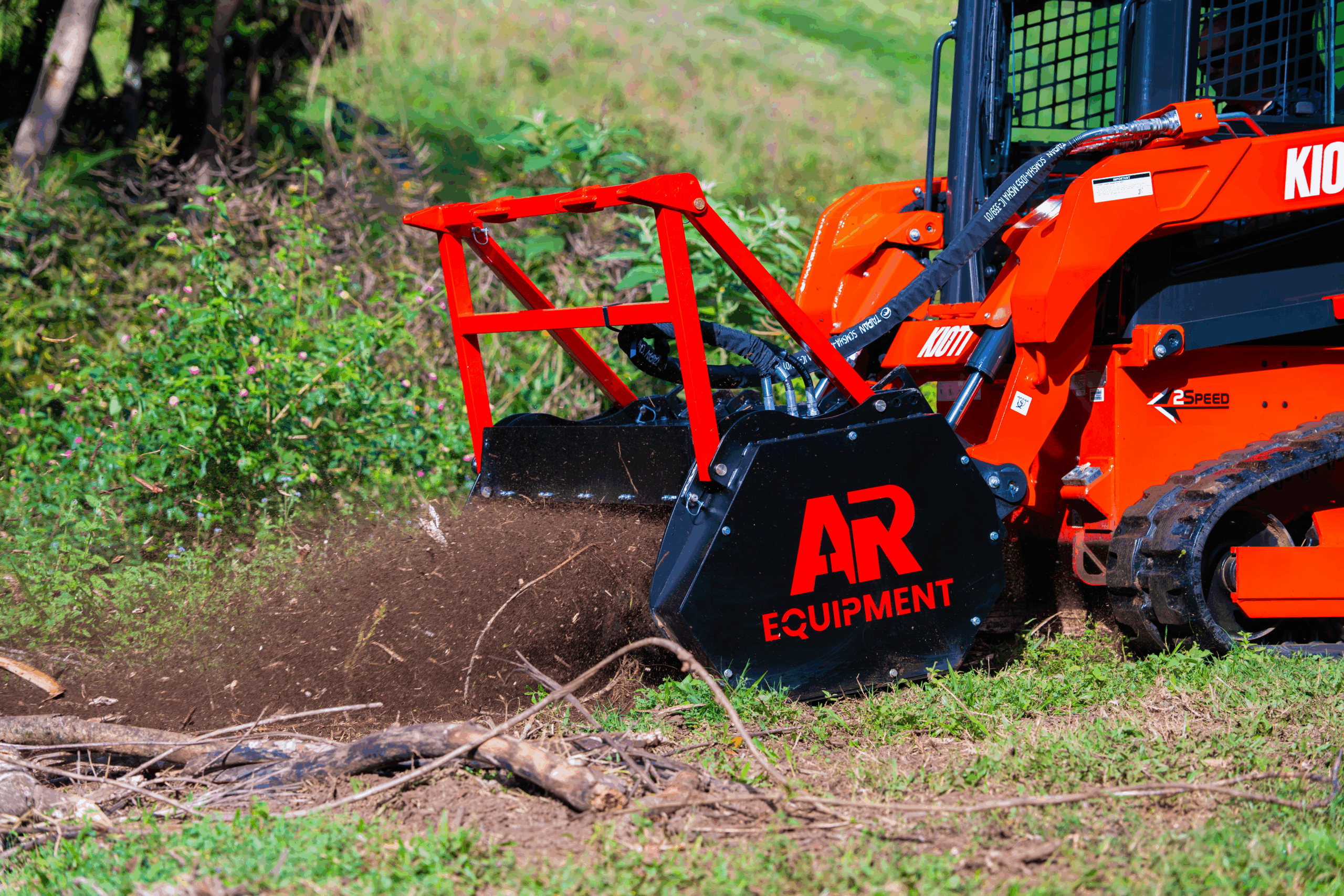

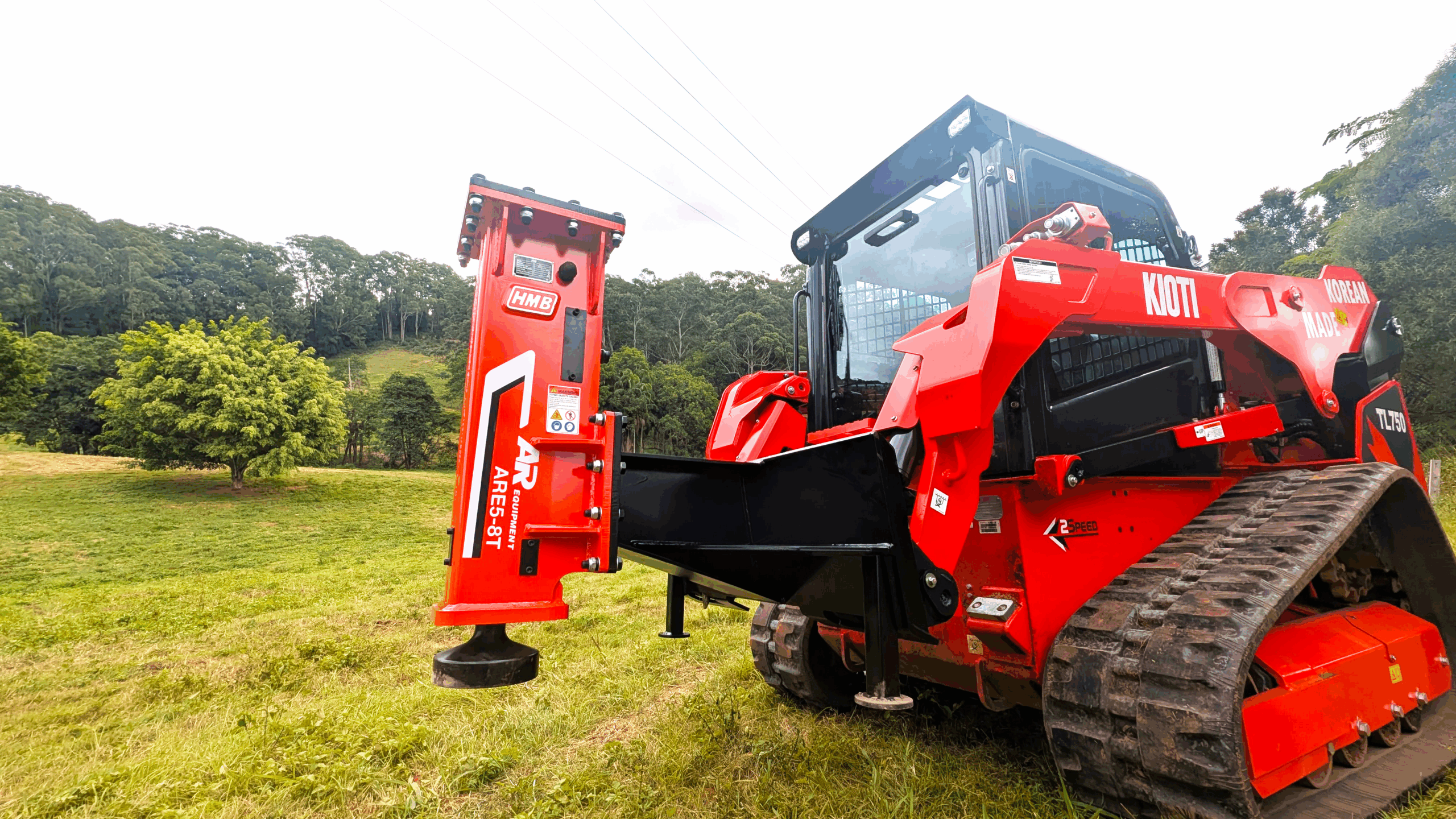

Additional attachments and specialised tools quickly escalate costs. Extra buckets and task-specific implements can add AUD 7,645 to AUD 15,290 to your purchase, though they significantly expand your machine’s operational versatility.

Operational Costs You Might Overlook

That purchase price? It’s just the beginning. Your excavator’s ongoing operational expenses can easily double your initial investment over its working life.

Fuel Usage by Excavator Size

Fuel consumption hits differently depending on what you’re operating. Mini excavators (under 6 tons) sip diesel at 1-2 litres per hour, while compact 1.5-ton models consume approximately 3.5 litres hourly. Step up to mid-size excavator (8-15 tons) and you’re looking at 15-20 litres per hour on average. Heavy-duty excavators (30-40 tons) are thirsty beasts, consuming 40-80 litres hourly.

Here’s the reality check: fuel represents about 30% of your operating expenses. Running a typical 20-ton excavator regularly? Expect annual fuel costs between AUD 12,231.92 and AUD 38,224.76. The good news is that newer models with advanced hydraulic systems can slash consumption by 25-30% compared to older machines.

Routine and Major Maintenance

Most operators underestimate maintenance costs until the bills start arriving. Annual excavator maintenance averages AUD 129,964.17 per machine for Australian contractors. Your routine maintenance includes oil changes (AUD 229.35–382.25), greasing (AUD 76.45–152.90), filter replacements (AUD 76.45–305.80), and hydraulic fluid replacement (AUD 305.80–611.60).

Major repairs deliver the real financial shock. Engine failures or hydraulic system breakdowns cost anywhere from AUD 1,528.99 to AUD 15,289.90. Undercarriage maintenance alone demands AUD 3,057.98 to AUD 12,231.92 annually. Smart budgeting means setting aside AUD 7,644.95 to AUD 27,521.82 yearly for total maintenance expenses.

Transport and Delivery Charges

Moving equipment between job sites creates another expense that catches owners off guard. Local transport within 200km runs approximately AUD 917.39-1,376.09 for mini excavators, while medium machines (8-15T) cost AUD 2,752.18-4,586.97 per move.

Long-distance moves (500-1000km) demand serious money: AUD 3,057.98-6,115.96 for small excavators and AUD 6,115.96-9,173.94 for medium machines. Don’t forget the extras—permit fees (AUD 229.35-458.70), pilot vehicles for oversized loads (AUD 3.82-5.35 per km), and interstate permits (AUD 152.90-764.50 per state).

What to Know Before You Buy

Smart excavator purchases go far beyond price comparison. Getting the right machine for your specific requirements can save you thousands in operational costs and prevent costly mistakes down the track.

Evaluating Your Excavator Needs

Start by honestly assessing your project’s specific demands. Large-scale developments require machines with serious reach and power, while detailed residential work calls for nimble mini excavators that won’t damage landscaping or structures.

The material you’re handling matters just as much. Breaking through hard rock demands different capabilities than moving soft soil or handling demolition debris. Your terrain plays a crucial role, too. Flat commercial sites have vastly different requirements compared to sloped residential blocks or uneven rural properties.

Note: Take time to measure access points, overhead clearances, and underground utilities before committing to any machine size.

Choosing the Right Size and Brand

Project scale directly determines your excavator requirements. Compact models excel in tight residential spaces where manoeuvrability matters most. Medium-sized machines suit commercial projects needing higher productivity without sacrificing versatility.

Check the machine’s reach, digging depth, and height limitations against your actual job requirements. These specifications aren’t just numbers on a spec sheet—they determine whether you can complete your work efficiently or struggle with an undersized machine.

Brand reputation significantly impacts long-term value. Established manufacturers like Caterpillar, Komatsu, and Hitachi maintain strong resale values thanks to proven reliability and parts availability. Focus on critical features: bucket capacity, engine power, and fuel efficiency directly affect how much material you can move and your daily operating costs.

Understanding Warranty and Support

New excavator warranties typically span 1 to 5 years, depending on the manufacturer. Extended warranties provide additional protection for expensive components like engines and transmissions, but verify exactly what’s covered—wear items like hydraulic seals often have limited coverage.

Service contracts, including scheduled maintenance and parts replacement, offer valuable peace of mind for busy contractors. These agreements help predict costs and minimise unexpected downtime that can derail project schedules.

Recommended Read: Contact AR Equipment for professional excavator attachment guidance and expert advice on selecting equipment that matches your specific needs.

Avoiding Common Cost Surprises

Think the purchase price and operational costs cover everything? Think again. Excavator ownership comes with several hidden expenses that catch unprepared buyers off guard.

Training and Certification Costs

Operator training isn’t just recommended—it’s a financial necessity that many buyers overlook entirely. Professional certification courses range from AUD 756.85 to AUD 993.84, depending on experience level and course duration. Inexperienced operators need comprehensive training programs costing around AUD 909.75, while experienced operators can qualify for shorter courses at AUD 756.85.

Here’s what happens when you skip proper training: premature equipment wear, costly accidents, and insurance complications that make the training fee look like pocket change.

Attachment Compatibility Issues

Wrong attachments create expensive headaches fast. Pin size, centre-to-centre measurements, or incorrect bushing dimensions mean attachments either won’t fit or operate dangerously. The result? You’re looking at expensive modifications or complete replacement purchases.

Before buying any attachment, verify hydraulic flow rates, quick hitch alignment, and connector compatibility. Contact AR Equipment for professional guidance on attachment compatibility—their expertise prevents costly mistakes when purchasing excavator equipment.

Storage and Yard Space Requirements

Storage might seem straightforward, but inadequate facilities create ongoing problems. Poor storage setups limit access when equipment needs maintenance or deployment. You need clear pathways for technicians and refuelling teams to reach machinery without shuffling other heavy equipment around.

Storage yard staff also require training in proper shutdown procedures, battery isolation, and secure storage practices—another cost layer that adds to your excavator’s total ownership expense.

Conclusion

Excavator ownership costs extend well beyond that initial purchase conversation with your dealer. The real expense equation includes purchase price, operational costs, maintenance schedules, transport fees, and those surprise expenses that catch unprepared buyers off guard.

Size drives everything. Mini excavators starting at AUD 30,580 work perfectly for smaller Australian projects, while extra-large models pushing past AUD 2 million suit major mining operations. Used machines offer genuine savings, provided you properly evaluate age, operating hours, maintenance records, and brand reputation.

Operational expenses hit hard and fast. Fuel alone represents 30% of your running costs—larger machines consume dramatically more diesel per hour. Maintenance requires both routine care and emergency repair budgets, especially for undercarriage work and hydraulic system failures.

Before making any purchase decision, assess your specific project demands thoroughly. Material types, work environment, and site accessibility all determine whether you need compact manoeuvrability or heavy-duty power. Match machine capacity to actual requirements rather than buying based on “what if” scenarios.

Don’t forget the hidden expenses. Operator training, attachment compatibility problems, and proper storage facilities all add to your total investment. Working with established Australian equipment providers ensures you get appropriate guidance throughout the selection process.

The excavator market provides options across every price point and capability level. Smart research and realistic planning help you navigate these decisions effectively. The right machine matched to your genuine needs delivers the best long-term value, regardless of the initial investment required.

Note: Contact reputable suppliers for professional advice on equipment selection and attachment compatibility to avoid costly mistakes during your purchase process.

FAQs

Q1. What is the typical price range for excavators in 2025? Excavator prices vary widely based on size and type. Mini excavators can start from around AUD 30,000, while medium-sized models typically range from AUD 100,000 to AUD 200,000. Large excavators for heavy-duty applications can exceed AUD 500,000.

Q2. How do operational costs impact the overall expense of owning an excavator? Operational costs significantly affect the total expense of excavator ownership. Fuel consumption, which can represent about 30% of operating expenses, varies by machine size. Annual maintenance costs can average around AUD 130,000 per machine, including routine tasks and major repairs.

Q3. What factors should be considered when choosing an excavator? When selecting an excavator, consider your project’s specific requirements, including the scale of work, type of material to be handled, and terrain. Evaluate the machine’s size, reach, depth capabilities, and height limitations. Also, consider brand reputation, bucket capacity, engine power, and fuel efficiency.

Q4. Are there any hidden costs associated with excavator ownership? Yes, several hidden costs can surprise unprepared buyers. These include operator training and certification costs (ranging from AUD 750 to AUD 1,000), potential attachment compatibility issues, and expenses related to proper storage and yard space requirements.

Q5. How does the age of an excavator affect its value? The age of an excavator significantly impacts its value. Typically, a 3-5 year old excavator retains 50-70% of its original value. Machines with fewer than 5,000 operating hours generally command stronger resale prices compared to those with higher usage.