Premium Hi-Torque Skid Steer Slasher

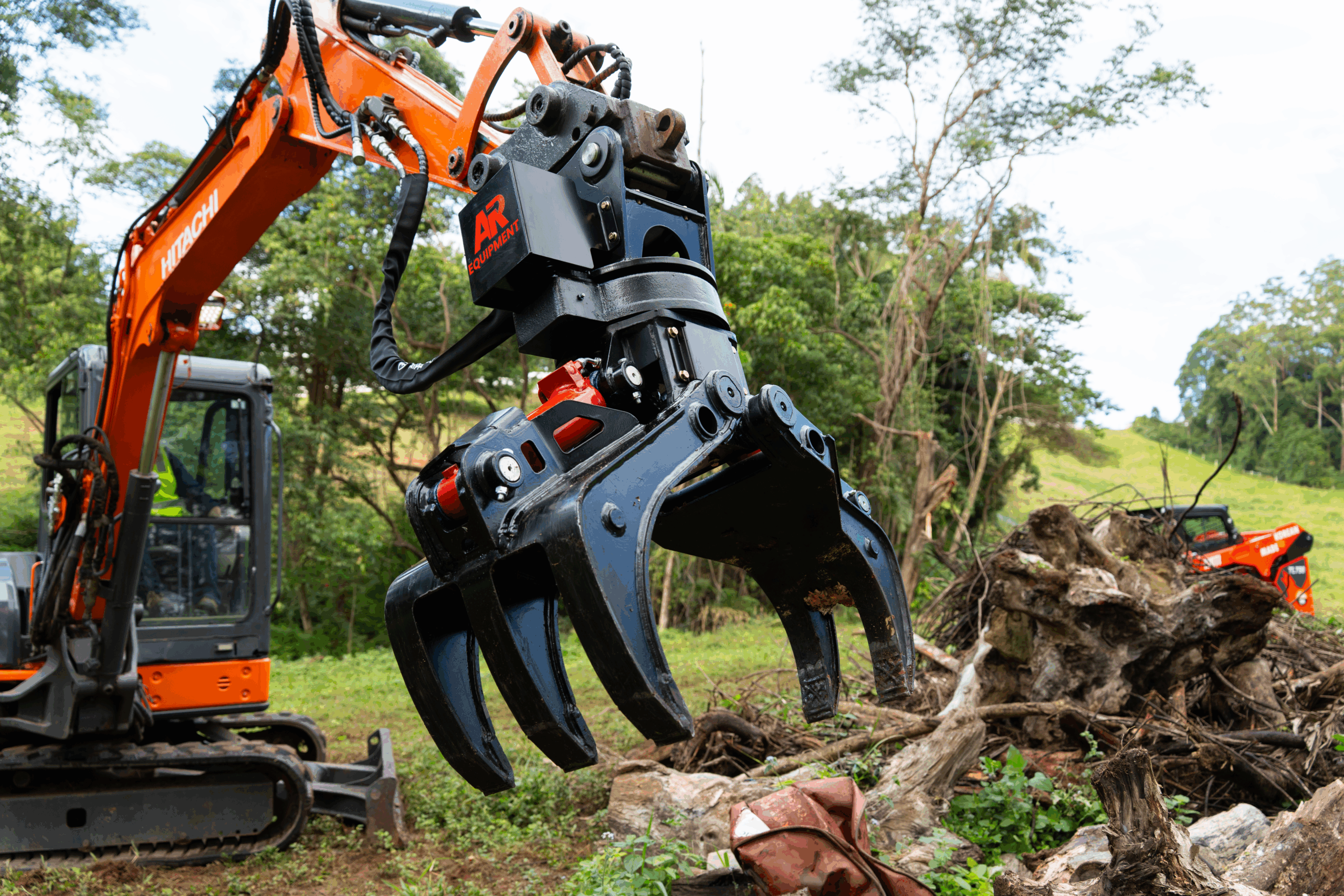

AR Equipment slashers are heavy-duty and engineered to deliver the highest torque in their class.

This means demanding work such as lantana, dense scrub, and small trees is handled with ease.

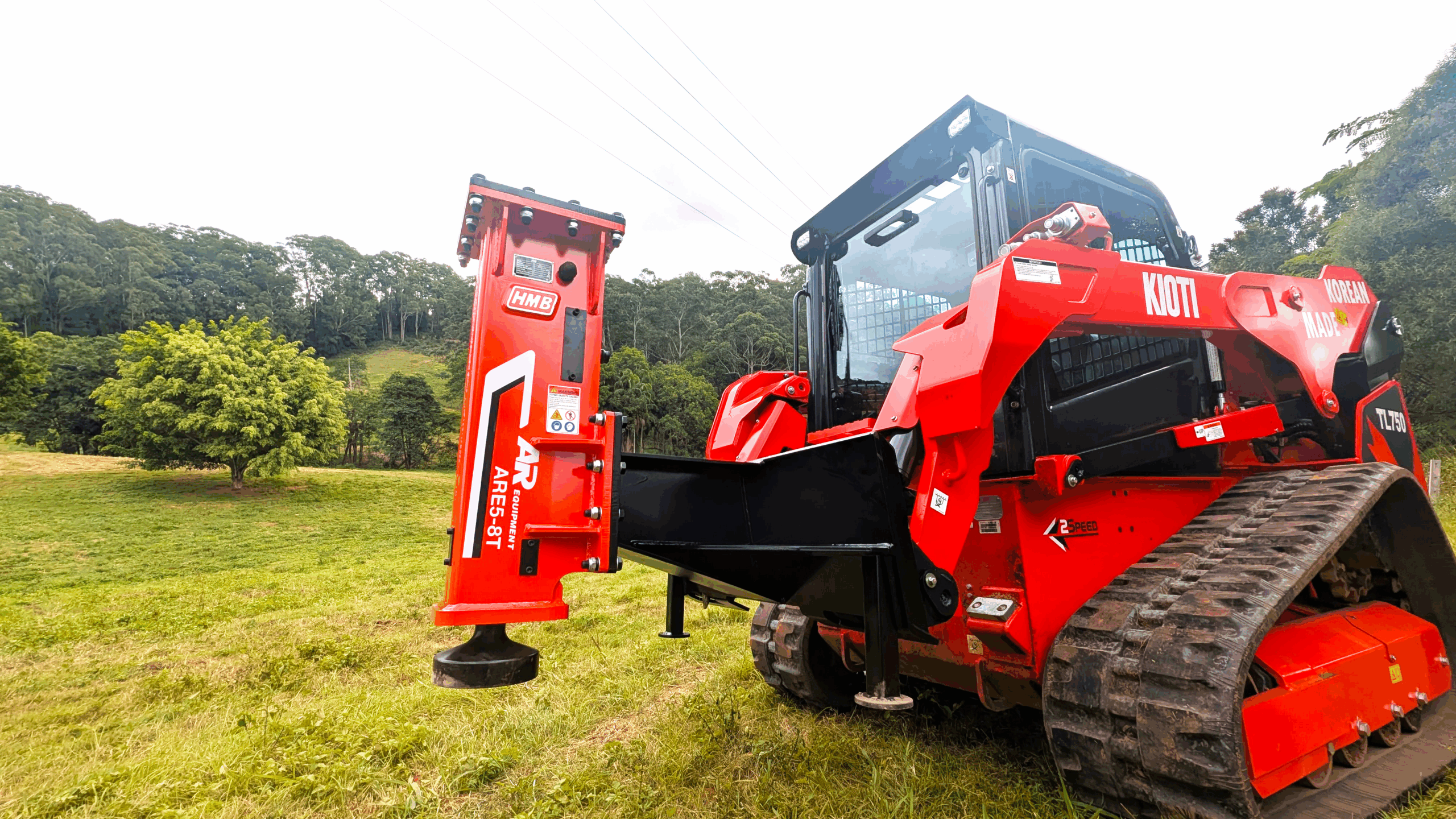

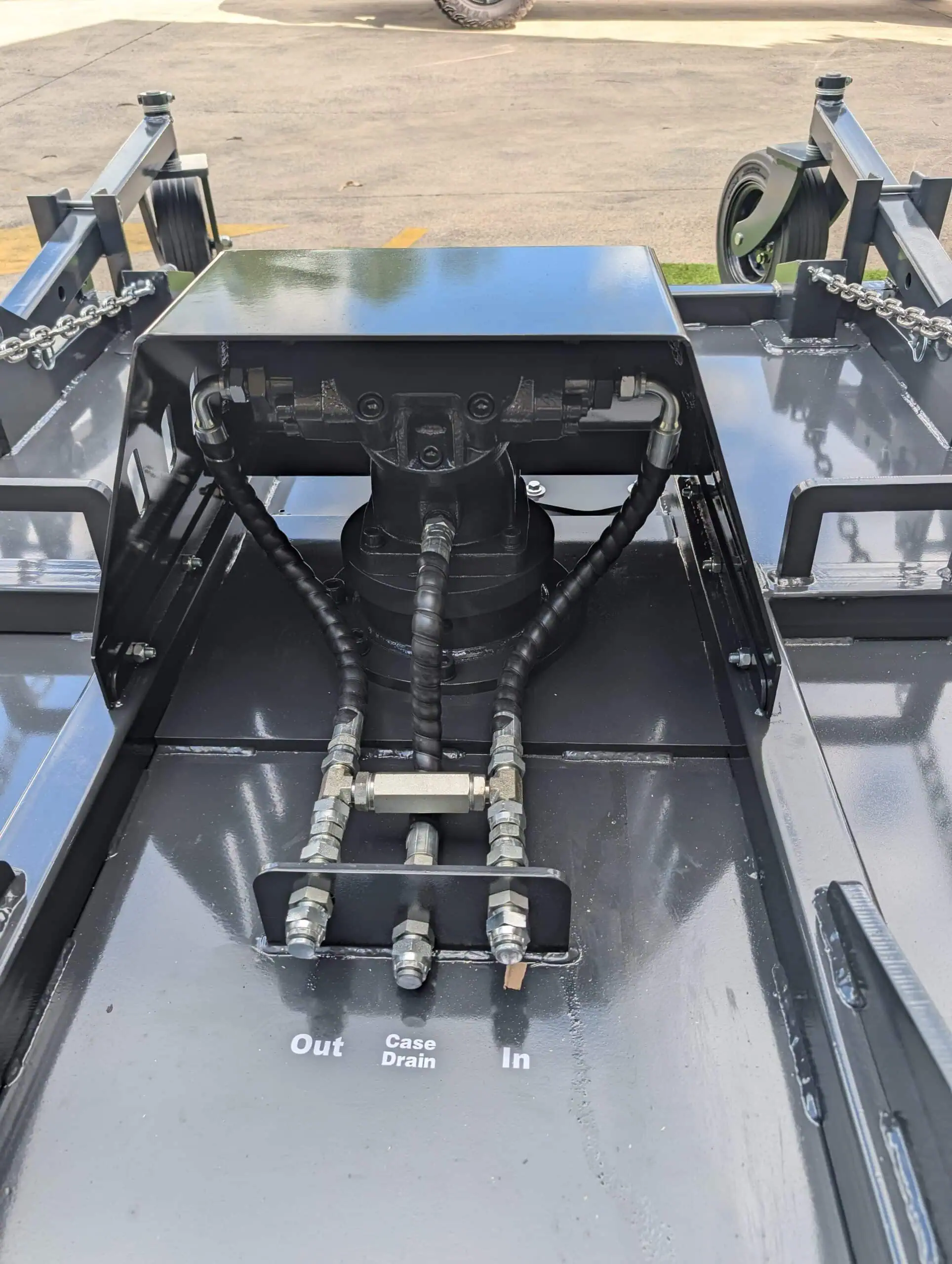

At the heart of the AR Slasher is a high-efficiency bent-axis piston motor, designed to extract maximum hydraulic performance from your machine.

Unlike inefficient gear motors that waste hydraulic horsepower, our drive system transfers more usable power directly to the slasher.

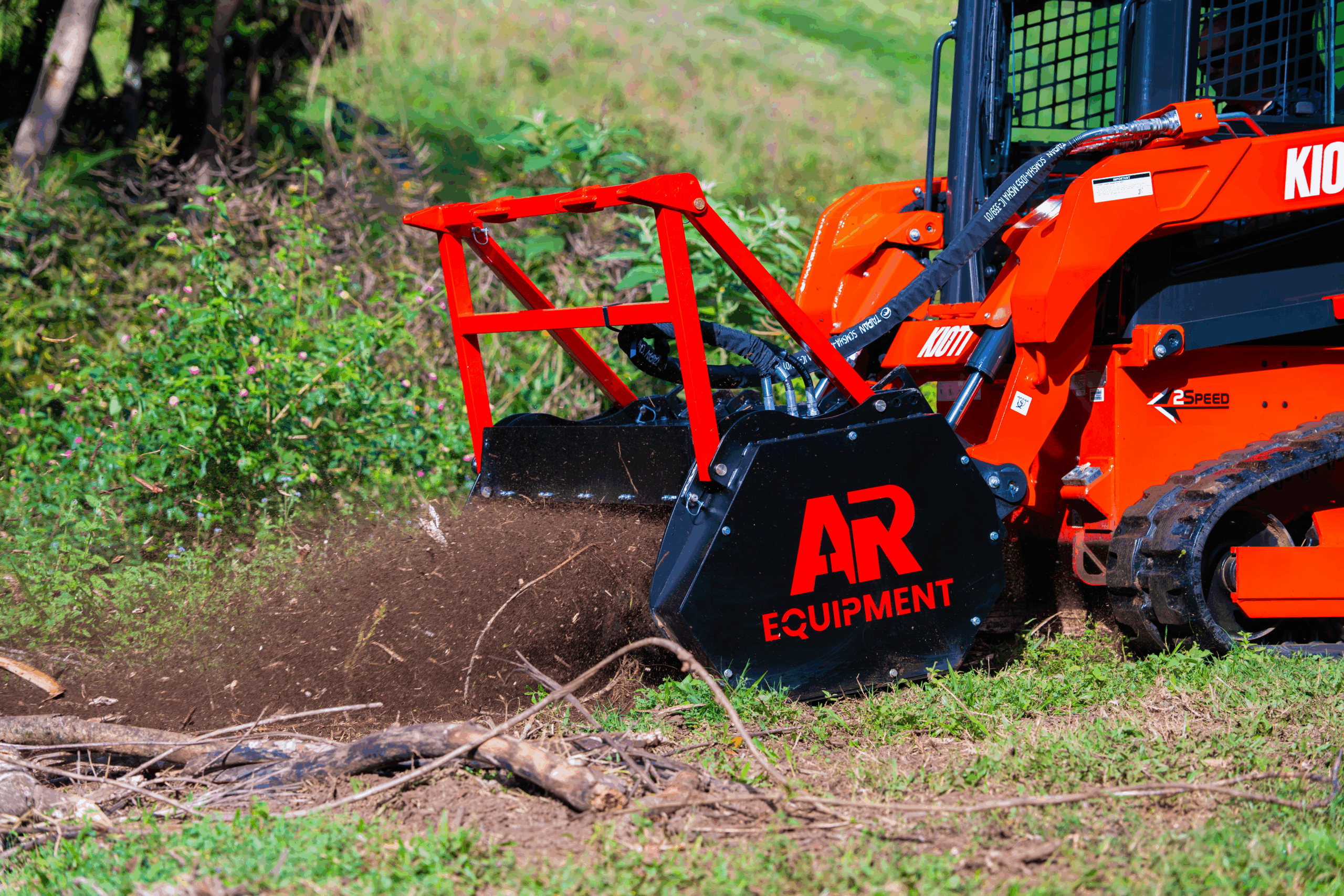

Coupled with our proven heavy duty twin blade cutting bar which is able to process heavier material than quad blade disc type slashers, giving faster recovery in heavy material, and class-leading productivity.

Whether you’re knocking down tall scrub, clearing lantana, or maintaining paddocks, the AR Slasher delivers uncompromising performance where it matters most.

| Model | Required Flow Rates (L/MIN) | Horsepower (HP) | Torque (NM) | RPM at the tip | Weight (KG) | Deck Width (MM) |

|---|---|---|---|---|---|---|

| 5FT | 40-90 | 43 @ 80LPM | 350 | 870 RPM | 600 | 1740 |

| 6FT | 70-120 | 63 @ 120LPM | 425 | 870 RPM | 700 | 1930 |

Why AR Slashers Are Different

Most skid steer slashers on the market are built to a price. AR Slashers are built to perform.

AR Slasher vs Conventional Skid Steer Slashers

Hydraulic Power & Drive System

Most competitors rely on standard gear motors. While cheaper to manufacture, gear motors are less efficient, operate under higher internal stress, and produce limited torque under load.

AR Slashers use a bent axis piston motor, delivering significantly higher torque, greater hydraulic efficiency, faster recovery when cutting heavy material, and superior long-term durability.

Terrain Following & Operator Fatigue

Rigid-mounted slashers struggle over uneven ground, requiring constant operator input to keep the deck level—quickly becoming tiring over long days.

The AR floating frame system automatically follows undulations, gullies, and contours via twin jockey wheels and a swivel chain hitch, allowing smooth mowing across large areas and around corners with minimal effort. When needed, it can still be lifted and used like a rigid mount for cutting tall scrub and small trees.

Durability in Heavy Vegetation

Many slashers are vulnerable when pushed into heavy brush or timber, particularly around wheel assemblies.

AR Slashers feature fold-away jockey wheels, allowing safe operation in heavy vegetation without risking damage.

Cut Quality & Material Processing

Disc-style blade systems often ride over sticks and timber, requiring multiple passes and creating uneven wind-rows.

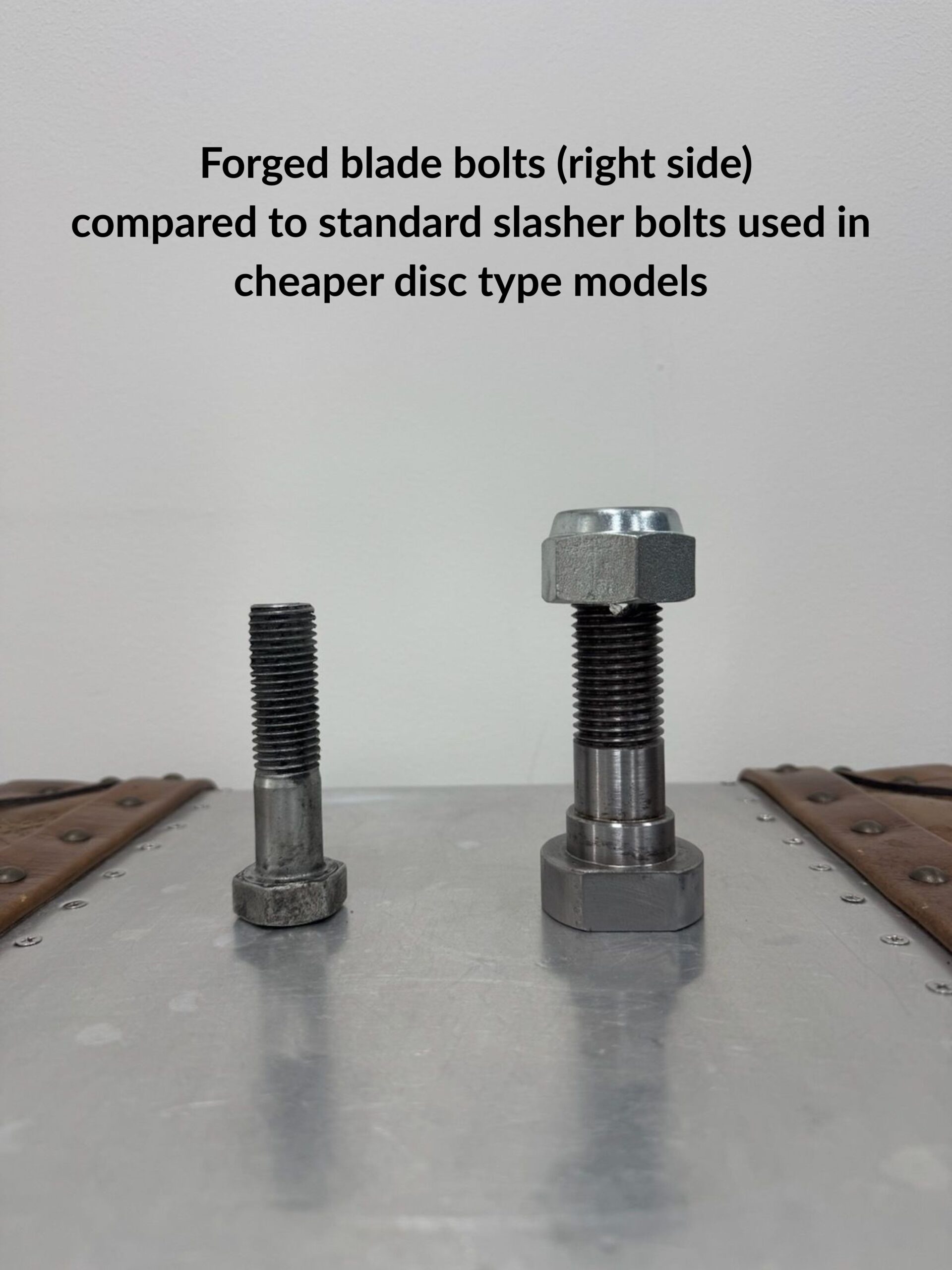

AR’s extreme-duty cutter bar assembly—supported by a heavily guarded bearing hub, premium blades, and forged blade bolts—handles timber over 3 inches with fewer passes, improved cut quality, and reduced wind-rowing.

Ground Protection & Manoeuvrability

Flat or light-duty skids can dig in and restrict turning, especially on soft or uneven ground.

Heavy-duty tubular side skids on AR Slashers prevent digging and allow smoother, tighter turns.

Frame Strength

Lightweight decks and minimal reinforcement may reduce upfront cost, but they don’t last in contractor environments.

AR Slashers are built with a 6mm deck and 8mm side skids, making them among the strongest frames in their class.

Maintenance & Serviceability

Many slashers require awkward access or multiple grease points, increasing downtime.

AR Slashers include top-access blade bolt covers for faster blade changes and feature just three grease points, keeping servicing simple and efficient.

The Bottom Line

If you want a basic slasher, there are plenty on the market.

If you want more power, better cut quality, reduced fatigue, and genuine contractor-grade durability, AR Slashers are in a class of their own.

Premium Hi-Torque Skid Steer Slasher

$9,990.00 $12,500.00 ex-GST

Category: Slasher

Need Finance?

Use our finance calculator to estimate your repayments.

Estimate your repayments

Disclaimer: Repayments are indicative only and subject to approval and credit assessment.

Key Features

- Bent Piston Motor – Offering 30% more torque

- Floating Deck

- Dual swing away jockey wheels

- Tube skids for easy turning

- Swivel mounting plate

- Forged Blade Bolts

Premium Hi-Torque Skid Steer Slasher

$9,990.00 $12,500.00 ex-GST

Need Finance?

Use our finance calculator to estimate your repayments.

Estimate your repayments

Disclaimer: Repayments are indicative only and subject to approval and credit assessment.

Key Features

- Bent Piston Motor – Offering 30% more torque

- Floating Deck

- Dual swing away jockey wheels

- Tube skids for easy turning

- Swivel mounting plate

- Forged Blade Bolts

Product Overview

AR Equipment slashers are heavy-duty and engineered to deliver the highest torque in their class.

This means demanding work such as lantana, dense scrub, and small trees is handled with ease.

At the heart of the AR Slasher is a high-efficiency bent-axis piston motor, designed to extract maximum hydraulic performance from your machine.

Unlike inefficient gear motors that waste hydraulic horsepower, our drive system transfers more usable power directly to the slasher.

Coupled with our proven heavy duty twin blade cutting bar which is able to process heavier material than quad blade disc type slashers, giving faster recovery in heavy material, and class-leading productivity.

Whether you’re knocking down tall scrub, clearing lantana, or maintaining paddocks, the AR Slasher delivers uncompromising performance where it matters most.

| Model | Required Flow Rates (L/MIN) | Horsepower (HP) | Torque (NM) | RPM at the tip | Weight (KG) | Deck Width (MM) |

|---|---|---|---|---|---|---|

| 5FT | 40-90 | 43 @ 80LPM | 350 | 870 RPM | 600 | 1740 |

| 6FT | 70-120 | 63 @ 120LPM | 425 | 870 RPM | 700 | 1930 |

Why AR Slashers Are Different

Most skid steer slashers on the market are built to a price. AR Slashers are built to perform.AR Slasher vs Conventional Skid Steer Slashers

Hydraulic Power & Drive System Most competitors rely on standard gear motors. While cheaper to manufacture, gear motors are less efficient, operate under higher internal stress, and produce limited torque under load. AR Slashers use a bent axis piston motor, delivering significantly higher torque, greater hydraulic efficiency, faster recovery when cutting heavy material, and superior long-term durability.Terrain Following & Operator Fatigue Rigid-mounted slashers struggle over uneven ground, requiring constant operator input to keep the deck level—quickly becoming tiring over long days. The AR floating frame system automatically follows undulations, gullies, and contours via twin jockey wheels and a swivel chain hitch, allowing smooth mowing across large areas and around corners with minimal effort. When needed, it can still be lifted and used like a rigid mount for cutting tall scrub and small trees.Durability in Heavy Vegetation Many slashers are vulnerable when pushed into heavy brush or timber, particularly around wheel assemblies. AR Slashers feature fold-away jockey wheels, allowing safe operation in heavy vegetation without risking damage.Cut Quality & Material Processing Disc-style blade systems often ride over sticks and timber, requiring multiple passes and creating uneven wind-rows. AR’s extreme-duty cutter bar assembly—supported by a heavily guarded bearing hub, premium blades, and forged blade bolts—handles timber over 3 inches with fewer passes, improved cut quality, and reduced wind-rowing.Ground Protection & Manoeuvrability Flat or light-duty skids can dig in and restrict turning, especially on soft or uneven ground. Heavy-duty tubular side skids on AR Slashers prevent digging and allow smoother, tighter turns.Frame Strength Lightweight decks and minimal reinforcement may reduce upfront cost, but they don’t last in contractor environments. AR Slashers are built with a 6mm deck and 8mm side skids, making them among the strongest frames in their class.Maintenance & Serviceability Many slashers require awkward access or multiple grease points, increasing downtime. AR Slashers include top-access blade bolt covers for faster blade changes and feature just three grease points, keeping servicing simple and efficient.The Bottom Line

If you want a basic slasher, there are plenty on the market. If you want more power, better cut quality, reduced fatigue, and genuine contractor-grade durability, AR Slashers are in a class of their own.

Enquire about our 2025 product catalogue

Access our comprehensive excavator and skid steer equipment catalogue, featuring complete specifications, pricing, and technical details for our full range of attachments and machinery solutions.

Get In Touch

Please fill out the form below and one of our friendly staff will get back to you