In construction and earthmoving, the terms digger and excavator are often used interchangeably. While there are mechanical differences between the two, focusing too much on the machine itself can distract from the attachments you’re using, which is what really determines the job efficiency.

In reality, most contractors don’t have complete freedom over the base machine they run. Site constraints, budgets, fleet availability, or hire agreements often dictate whether you’re operating a digger, a mini excavator, or a large crawler. What can be optimised, however, is the attachment. This choice often has a bigger impact on productivity, precision, and cost than the machine alone.

This blog breaks down the traditional differences between diggers and excavators, but more importantly, explains why selecting the right attachment for the job should be the priority.

Understanding the Machines

An excavator is typically a dedicated digging machine with a boom, dipper, bucket, and cab mounted on a rotating house. One of its defining features is its full 360-degree rotation, allowing operators to work efficiently across a wide area without repositioning the machine.

Diggers (often referring to backhoes or mini diggers) share similar core components but usually have a more limited swing range, around 180–200 degrees. Many also combine multiple functions, such as a backhoe on one end and a front loader on the other.

These design differences affect how the machines move and operate, but they don’t tell the full story of what the machine can actually do on site.

Attachments: The Source of Versatility

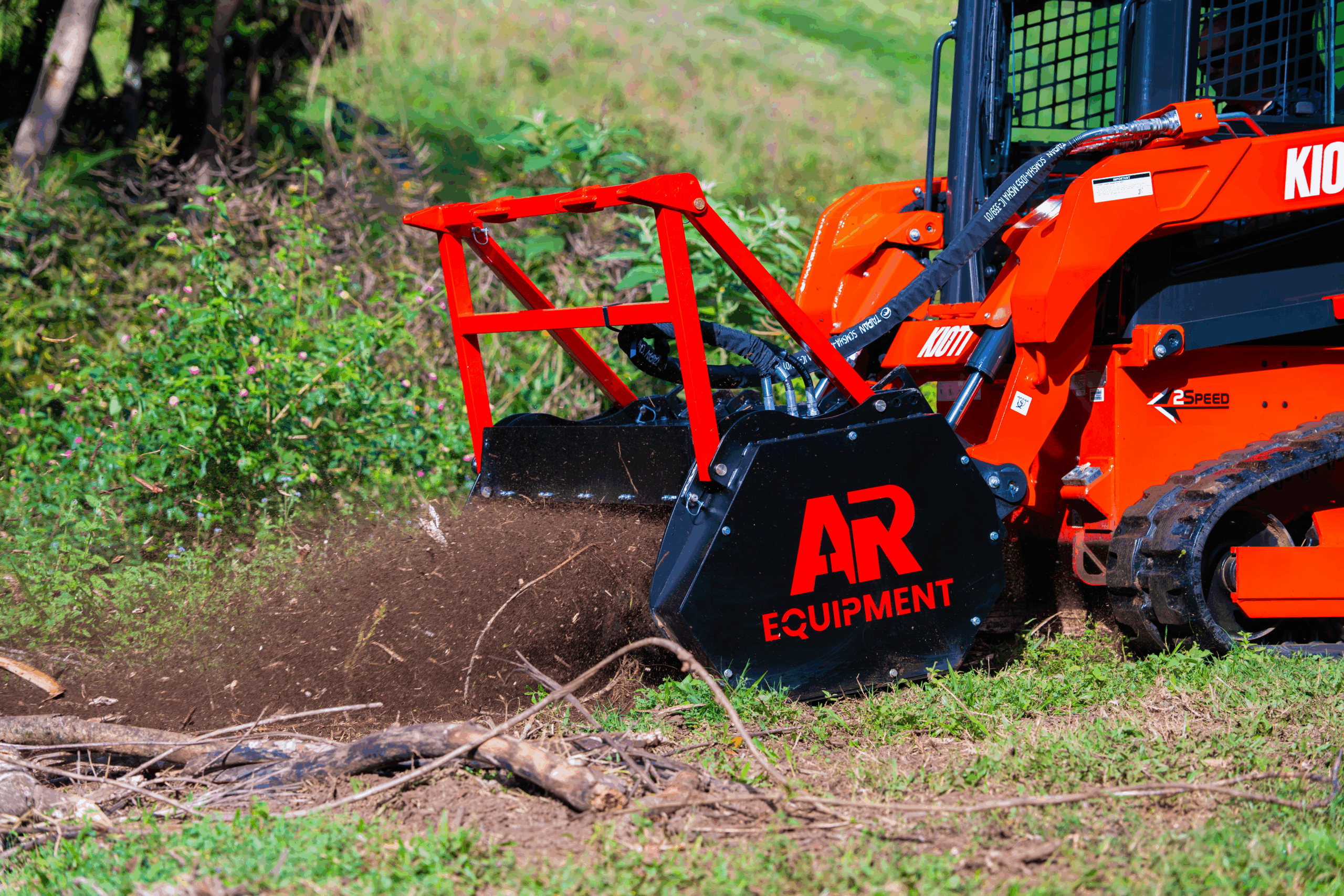

While base machines provide power and mobility, attachments define capability.

The same excavator can trench, drill, demolish, lift, grab, or level by simply changing the attachment. In many cases, a contractor can complete an entire project with one machine and several attachments, rather than switching machines entirely.

Common excavator and digger attachments include:

- Buckets (general purpose, trenching, tilt, or grading)

- Augers for drilling post holes and footings

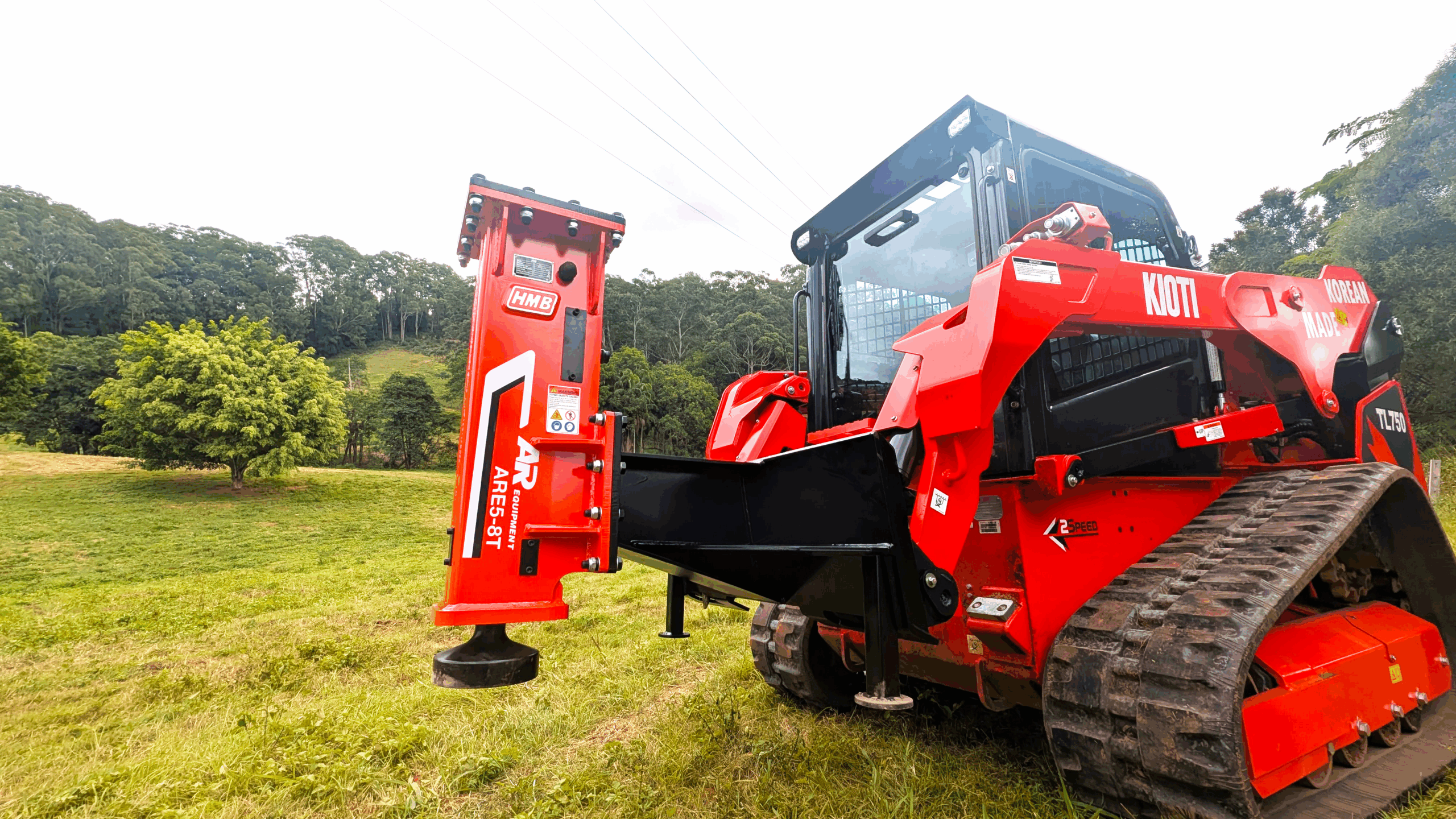

- Hydraulic breakers for concrete and rock

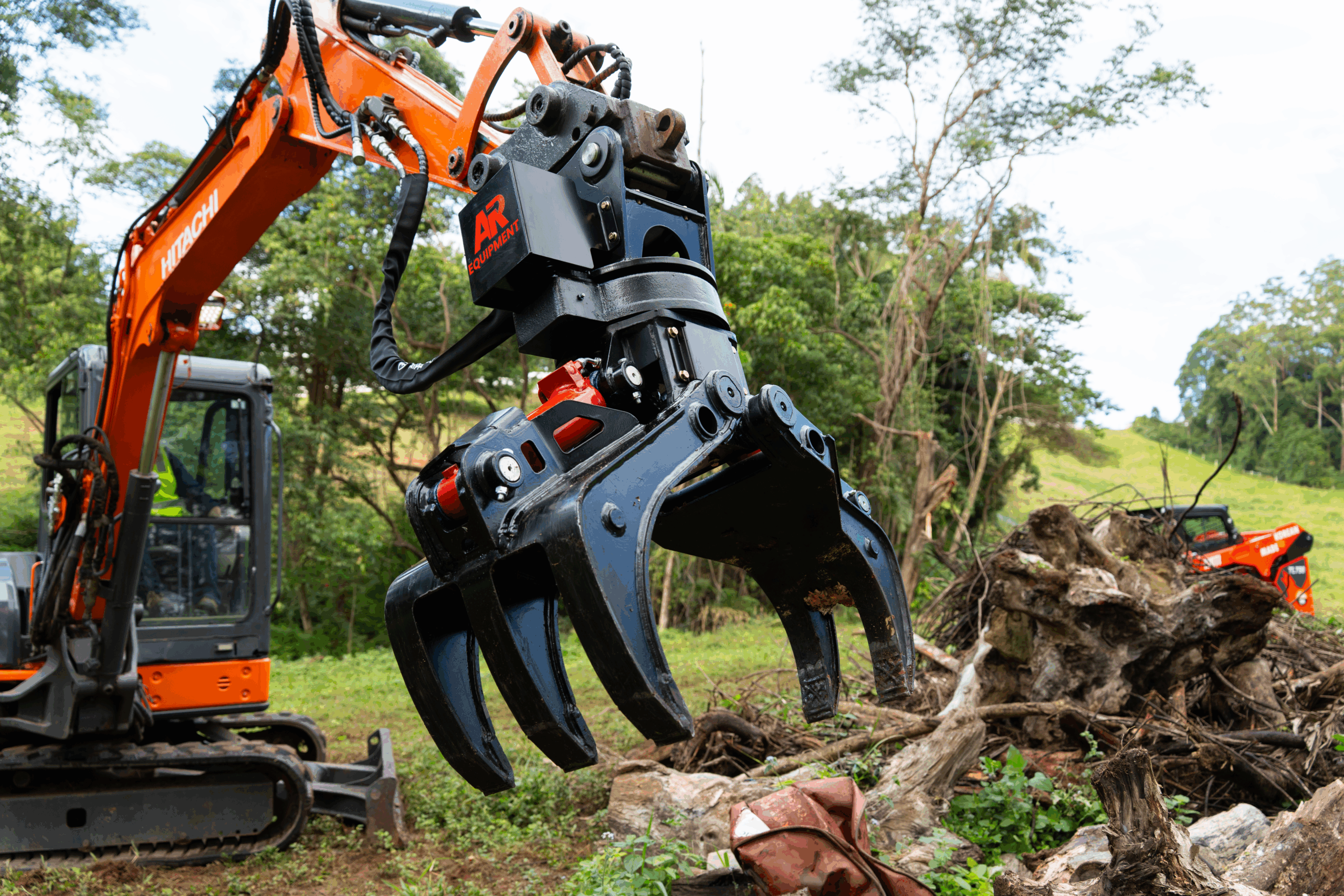

- Grapples for handling debris, timber, or scrap

- Rippers for hard ground

- Compaction wheels and plates

- Screening and sorting buckets

With the right attachment, even a smaller or more compact machine can outperform a larger one fitted with the wrong tool.

Matching the Attachment to the Job

Instead of asking “Do I need a digger or an excavator?”, a more productive question is:

“What task am I trying to complete?”

For example:

- Trenching for services may require a narrow trenching bucket rather than a larger machine.

- Post installation is faster and cleaner with an auger than with a standard bucket.

- Demolition efficiency depends more on the right breaker size than on machine weight alone.

- Landscaping and final trim work benefit from tilt buckets and grading attachments that improve accuracy.

Even machines traditionally seen as limited (such as mini diggers) become highly capable when paired with purpose-built attachments designed for confined spaces.

Performance Isn’t Just About Size

Larger excavators deliver more power, but power alone doesn’t guarantee efficiency. Using an oversized bucket or an incorrect attachment can increase fuel use, reduce control, and slow cycle times.

Smaller machines fitted with correctly sized attachments often:

- Use less fuel

- Reduce ground disturbance

- Improve accuracy

- Lower transport and operating costs

Attachments allow operators to tailor performance to the job, rather than forcing the job to suit the machine.

One Machine, Multiple Roles

Modern worksites increasingly rely on machines that can adapt quickly. Attachments make that possible.

An excavator can move from digging footings in the morning, to lifting materials in the afternoon, to site clean-up by day’s end (all without changing the base machine). This flexibility reduces downtime, minimises fleet size, and improves overall project flow.

Diggers benefit in the same way, especially on residential and urban sites where space is limited and efficiency matters.

Choosing Smarter, Not Bigger

The debate between diggers and excavators often overlooks the most practical consideration: attachments determine outcomes. While machine type affects reach, rotation, and mobility, the attachment controls how effectively the task is completed.

Rather than focusing solely on which machine to buy or hire, contractors see better results by investing in:

- The correct attachment type

- Proper sizing for their machine

- High-quality hydraulic compatibility

- Attachments suited to their most common tasks

Important Takeaways

Diggers and excavators each have their place, but the real difference on site comes down to what’s attached to the boom. A well-chosen attachment can turn an average machine into a highly efficient, task-specific tool.

By prioritising attachments over machine labels, operators can work smarter, reduce costs, and get more value out of the equipment they already have. Whether you’re trenching, drilling, lifting, demolishing, or finishing, the right attachment makes all the difference.