The debate around Chinese-made goods has been raging for years. In the attachment industry, the question remains: are Australian, US, or European-built attachments truly superior?

The answer isn’t simple. A lack of regulation in the industry has led to confusion, misinformation, and even outright deception. Sellers often market their products as “like for like,” yet prices can vary wildly. Some companies push outrageous warranties, longer than those offered on premium European or US-built equipment, on their cheapest Chinese imports. But when problems arise, “user error” is often blamed, and warranties become meaningless unless you’re ready to wage a legal battle.

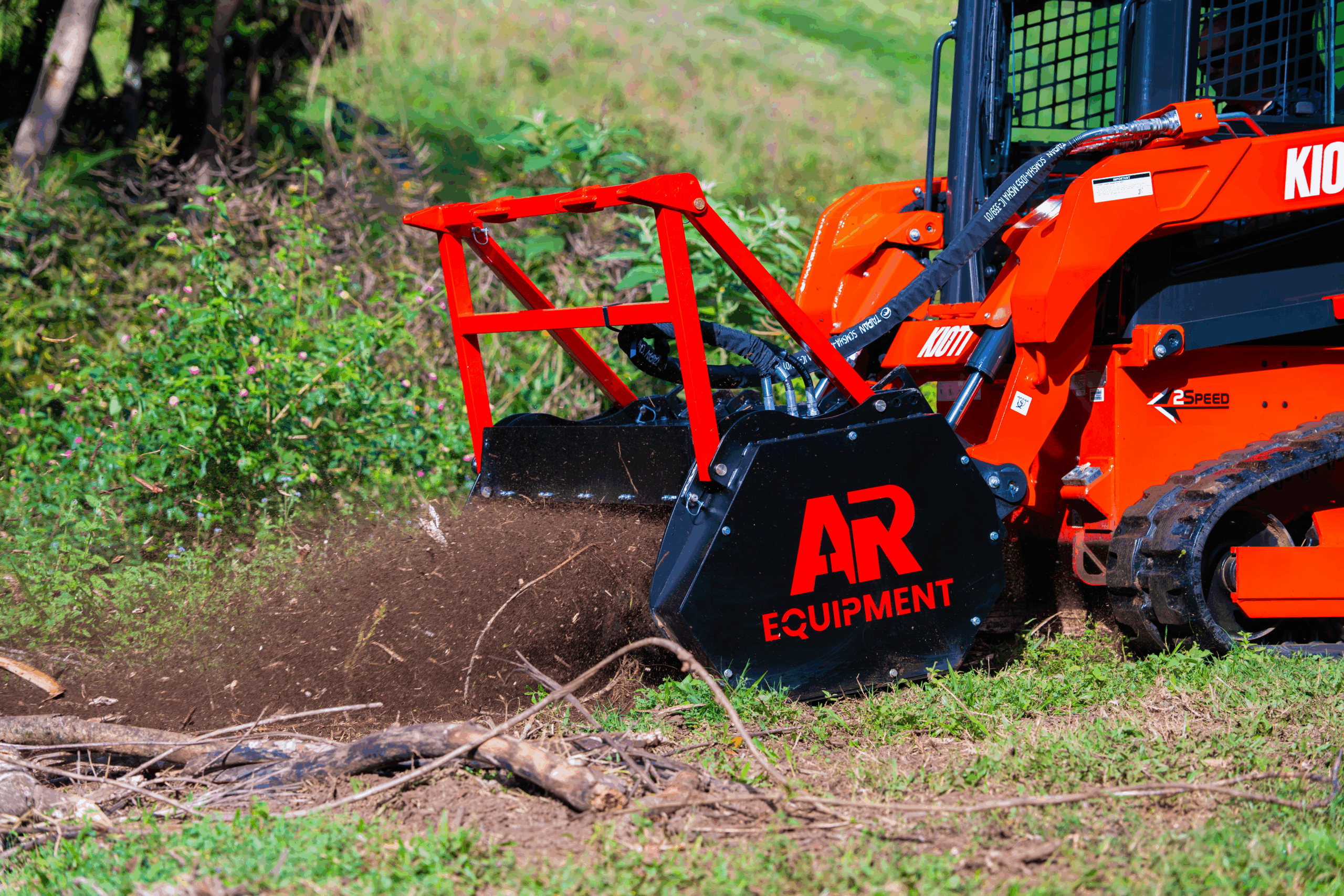

Here’s the truth: China has embraced automation and manufacturing technology in a way that rivals or even surpasses some Western countries. Just as Japan surprised the world with its quality revolution in the ‘70s and ‘80s, China is now capable of producing high-end products—particularly when working alongside Australian engineers and designers.

So, can you buy a high-quality Chinese attachment? The answer is: yes and no.

The Real Challenge: Sorting Quality from Quantity

The real question isn’t whether China can make quality attachments—it’s which suppliers are building for quality and long-term reputation, and which are pumping out cheap products for a quick sale.

The harsh reality is that plenty of Chinese suppliers still cater to sellers chasing the lowest price. This makes it tough for Australian buyers to know whether they’re getting genuine value or simply gambling on inferior steel and workmanship.

What Buyers Should Watch Out For

Here’s how to navigate the minefield:

1. If it sounds too good to be true, it probably is.

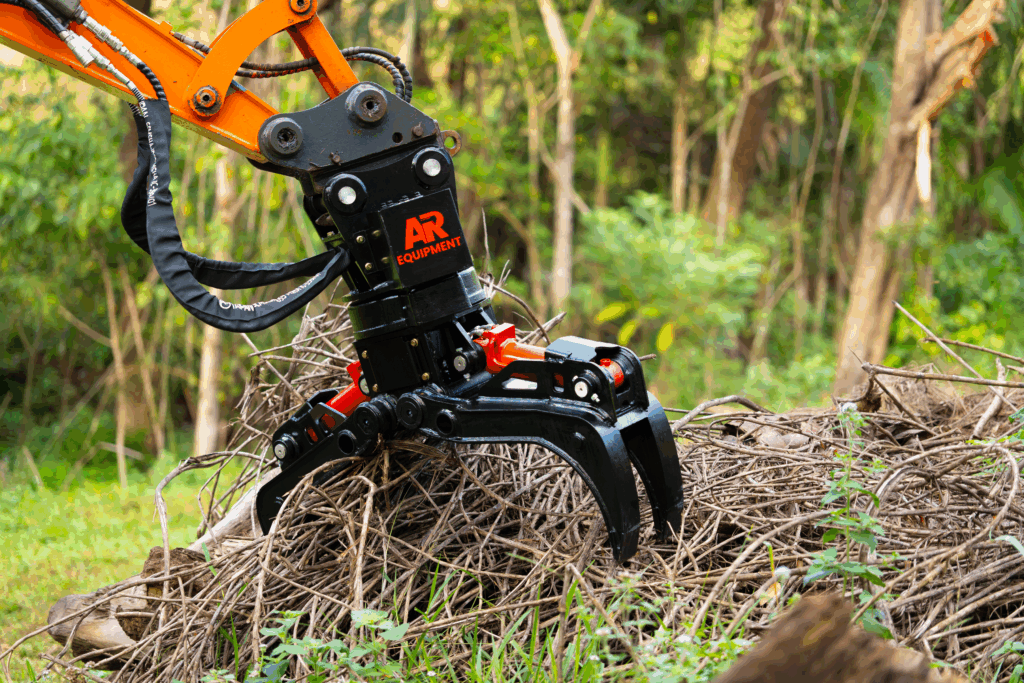

A supplier claiming to sell a 20-ton grab made of Hardox 400 for $5,000 is selling a fantasy. Price up 1.2 tons of Hardox 400 steel, cut and rolled, and you’ll see why that’s impossible.

2. Check what’s behind the sale.

Does the seller have a workshop?

Do they employ tradesmen, fabricators, or engineers in Australia?

Can they provide references from long-term customers?

Online reviews can be easily faked, so rely on real conversations, not star ratings.

3. Consider parts availability.

If there’s already a wait for your initial product, what are the chances spare parts will be available quickly when something breaks? Downtime is expensive.

4. Inspect component quality.

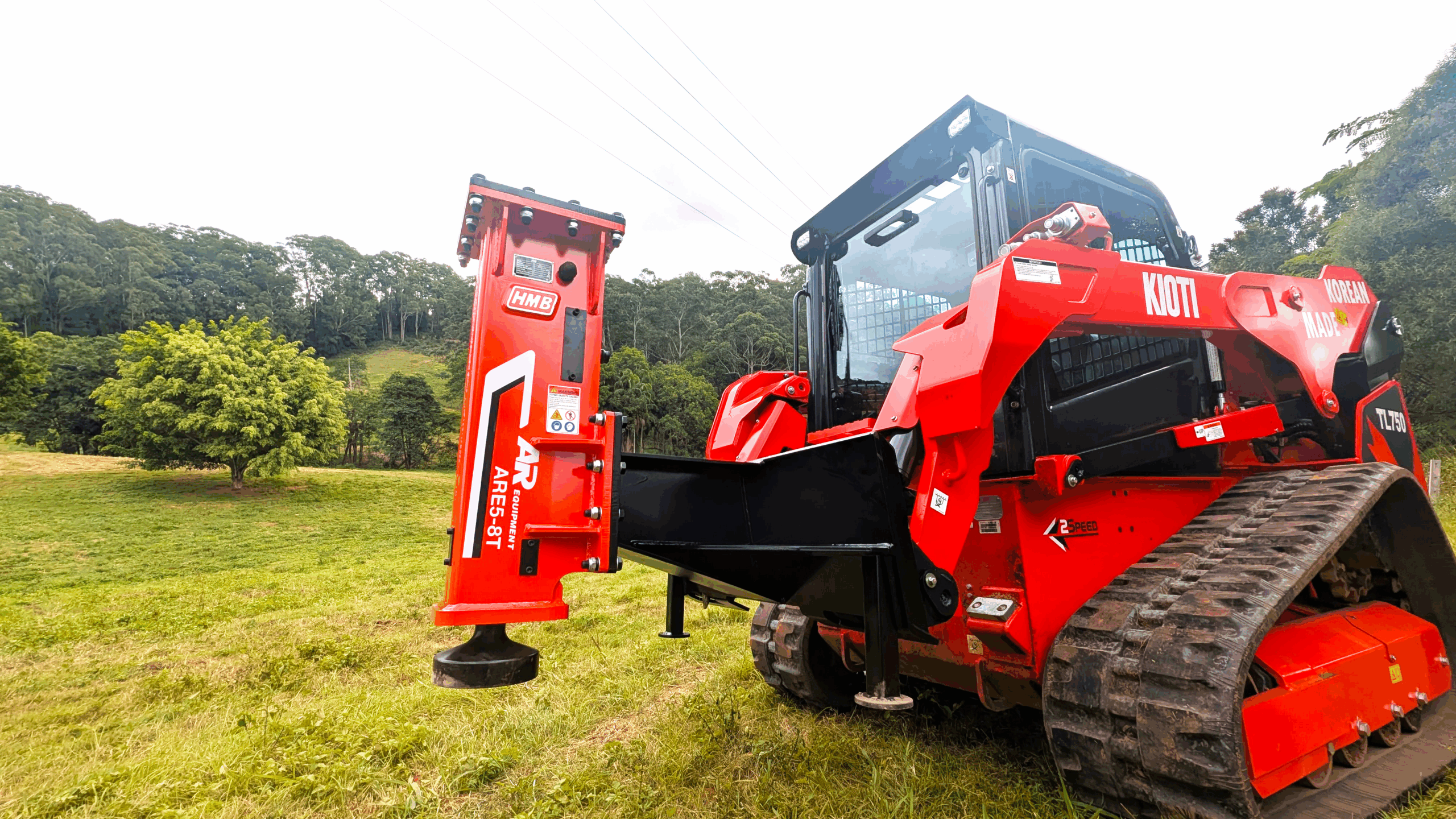

Hydraulic motors, breakers, and key components should be high-end. If these fail, the cost isn’t just repair—it’s a machine down, potentially full of metal in the hydraulics, giving a whole other headache and expense.

Price vs. Quality: Finding the Sweet Spot

A good rule of thumb:

Products priced around half to two-thirds of European or Australian equivalents are more likely to be quality Chinese builds, often using steels like NM400, NM500, or Q460.

Products priced at well under half are almost always built with cheaper Q345 steel and shortcuts that will cost you more in the long run.

The gap between a bargain and a smart investment is often only a few thousand dollars—an amount easily outweighed by reduced downtime and better long-term reliability.

The Bottom Line

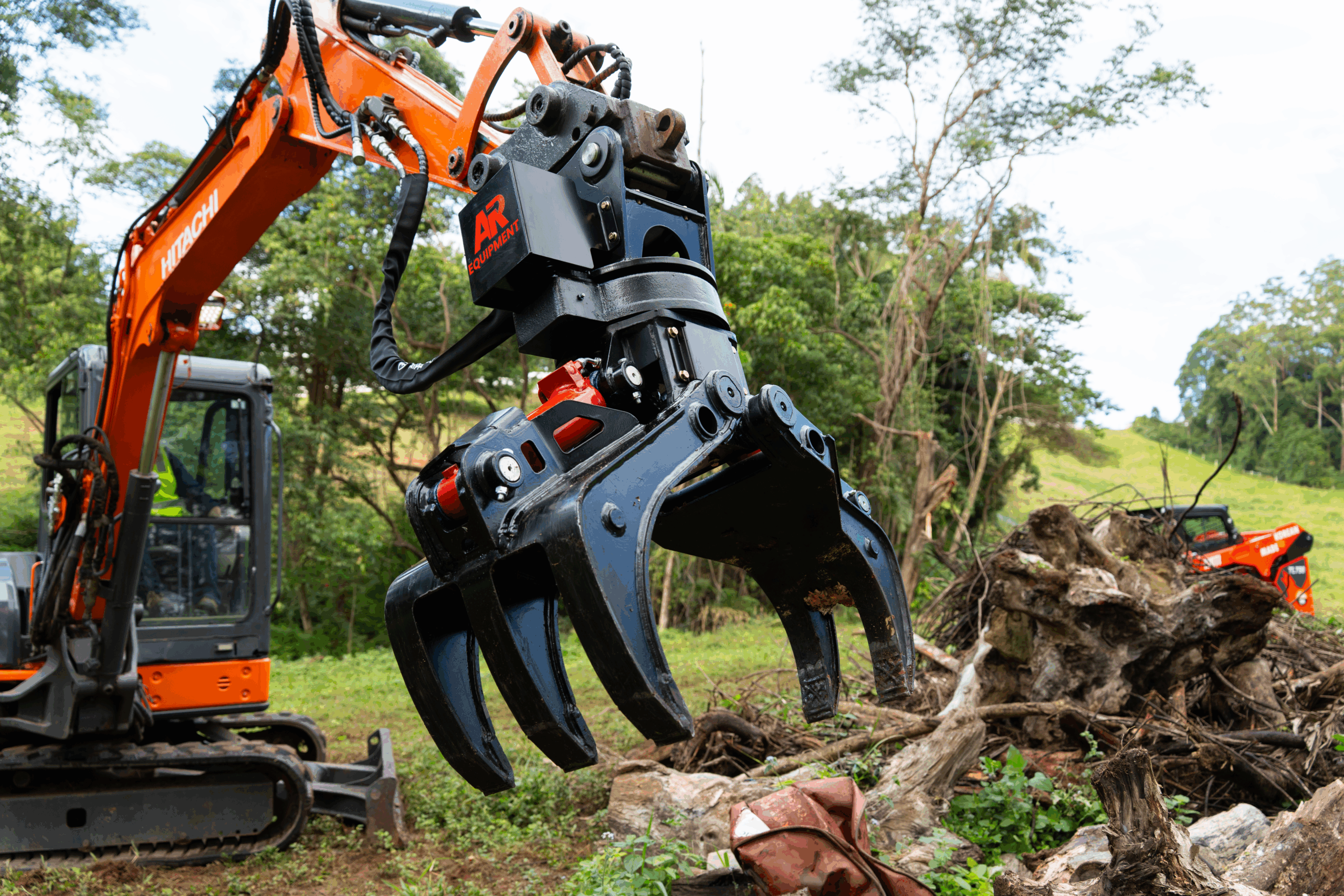

Yes, it’s possible to buy Chinese-built attachments that rival US, Australian, and European products. But they’re not the 20-ton rotating grab for $8,000. Look for the $25,000–$35,000 Chinese option versus the $50,000–$60,000 Western-built equivalent, and you’ll be closer to a product worth your money.

Smart buyers don’t just shop on price—they invest in supplier credibility, local support, and proven quality. In a market flooded with misinformation, that’s how you separate myth from reality.