What makes the difference between an efficient construction operation and one that struggles with productivity? Often, it comes down to having the right tools for each specific task.

Excavator attachments turn these machines into specialised workhorses capable of handling diverse jobsite challenges. Consider this: excavators account for 53% of all global equipment sales, and their popularity stems largely from their adaptability when equipped with the right accessories.

Your excavator handles far more than basic digging operations. These machines excel at trenching, demolition, material handling, and land grading when paired with appropriate attachments. The right accessory essentially gives you multiple machines in one, delivering substantially more value across your projects.

Choosing the right excavator attachments directly impacts your operational efficiency and project outcomes. The question becomes: do you need to dig, grade, dredge, drill, handle materials, or remove vegetation? Each task demands specific capabilities, and the right attachment makes the crucial difference between struggling through a job and completing it efficiently.

This guide examines eight essential excavator attachments that Australian contractors should know about. Understanding these tools helps you maximise productivity and tackle diverse challenges on your next project with confidence.

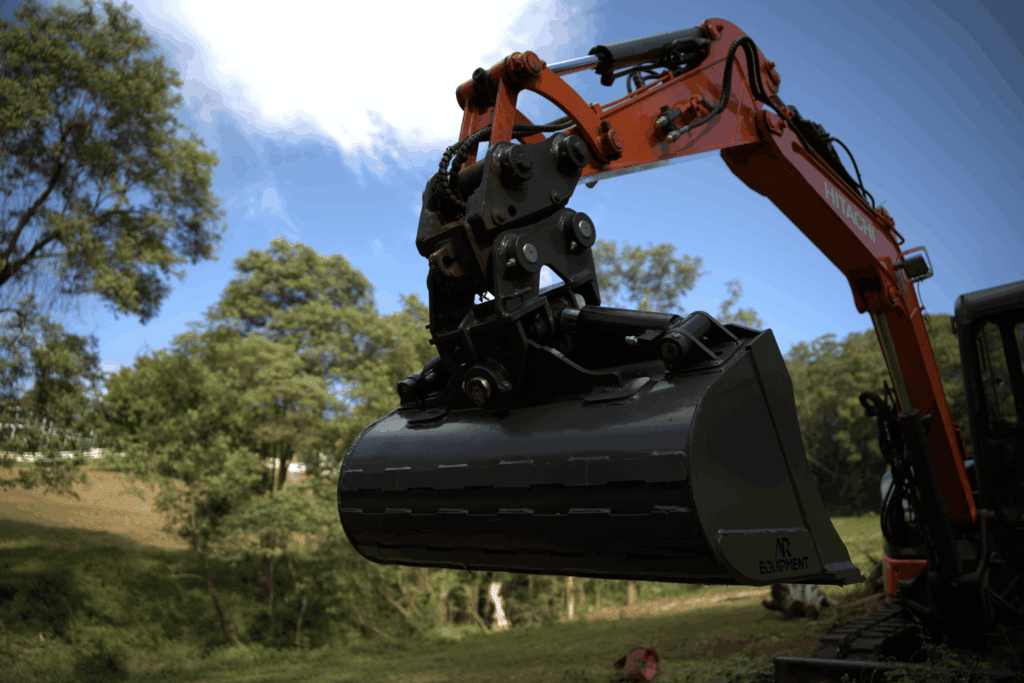

Bucket Attachments

Bucket attachments represent the most fundamental tools in any excavator’s arsenal. These versatile containers mount directly to your excavator, delivering the precision and efficiency needed for digging, moving, and handling materials across diverse construction applications. Each bucket type serves distinct purposes, making selection critical for optimal jobsite performance.

What is a Bucket Attachment

Think of bucket attachments as specialised containers engineered for specific excavation and material handling tasks. The general purpose bucket (GP bucket) handles everyday operations—digging, trenching, and moving standard materials like soil, sand, and gravel.

The bucket family extends well beyond basic options:

- Digging buckets – Sharp teeth along the cutting edge penetrate hard surfaces with ease

- Grading/finishing buckets – Wider, shallower profiles with flat edges create smooth, level surfaces

- Rock buckets – Heavy-duty reinforcement and aggressive teeth tackle the toughest materials

- Clean-up buckets – Straight edges and increased width deliver precise final grading

- Tilt buckets – Angling capability up to 45 degrees left or right, handles slope work efficiently

- Skeleton/screening buckets – Built-in slots or grids separate fine materials during operation

Construction quality varies significantly across bucket types. Standard models feature high-grade steel construction, while premium options incorporate materials like HARDOX450 and NM400 for exceptional durability in demanding conditions.

How Bucket Attachments Work

Modern bucket systems connect through quick-hitch mechanisms, allowing operators to switch between different types without leaving the cab. Once mounted, the bucket responds to hydraulic commands through the excavator’s arm movement system.

Bucket effectiveness relies heavily on design-specific features. Digging variants utilise cutting-edge teeth to break through compacted materials, while grading buckets employ smooth edges that create uniform surfaces when dragged across terrain.

Advanced models incorporate hydraulic functions for specialised tasks. Tilt buckets include independent hydraulic cylinders, enabling the bucket to pivot separately from the excavator arm—perfect for angled digging and precise grading on uneven ground.

Best Use Cases for Bucket Attachments

Bucket selection directly impacts job efficiency, making the right choice crucial for project success. General-purpose buckets offer versatility for contractors managing diverse excavation tasks with a single attachment.

Heavy-duty buckets become essential when handling challenging materials like rock or heavily compacted soil. Their reinforced construction and penetrating teeth make them indispensable for mining operations and major construction projects where standard equipment would fail prematurely.

Precision work demands specific solutions. Grading buckets (also called ditch cleaning buckets) excel at creating ditches and trenches with smooth, consistent results. Their wide, flat profile allows operators to achieve level surfaces efficiently—ideal for foundation preparation and drainage channel construction.

Landscaping and final grading benefit significantly from tilt bucket capabilities. The independent angling function creates slopes and contours far more efficiently than standard bucket operations.

Important note: Utility buckets deserve special consideration for urban projects. These specialised attachments reduce utility strike risks when excavating near underground pipes and cables—a critical safety feature for developed areas.

Successful bucket selection considers material type, precision requirements, jobsite conditions, and your specific excavator model. Matching the right bucket to each task boosts productivity while protecting your equipment investment.

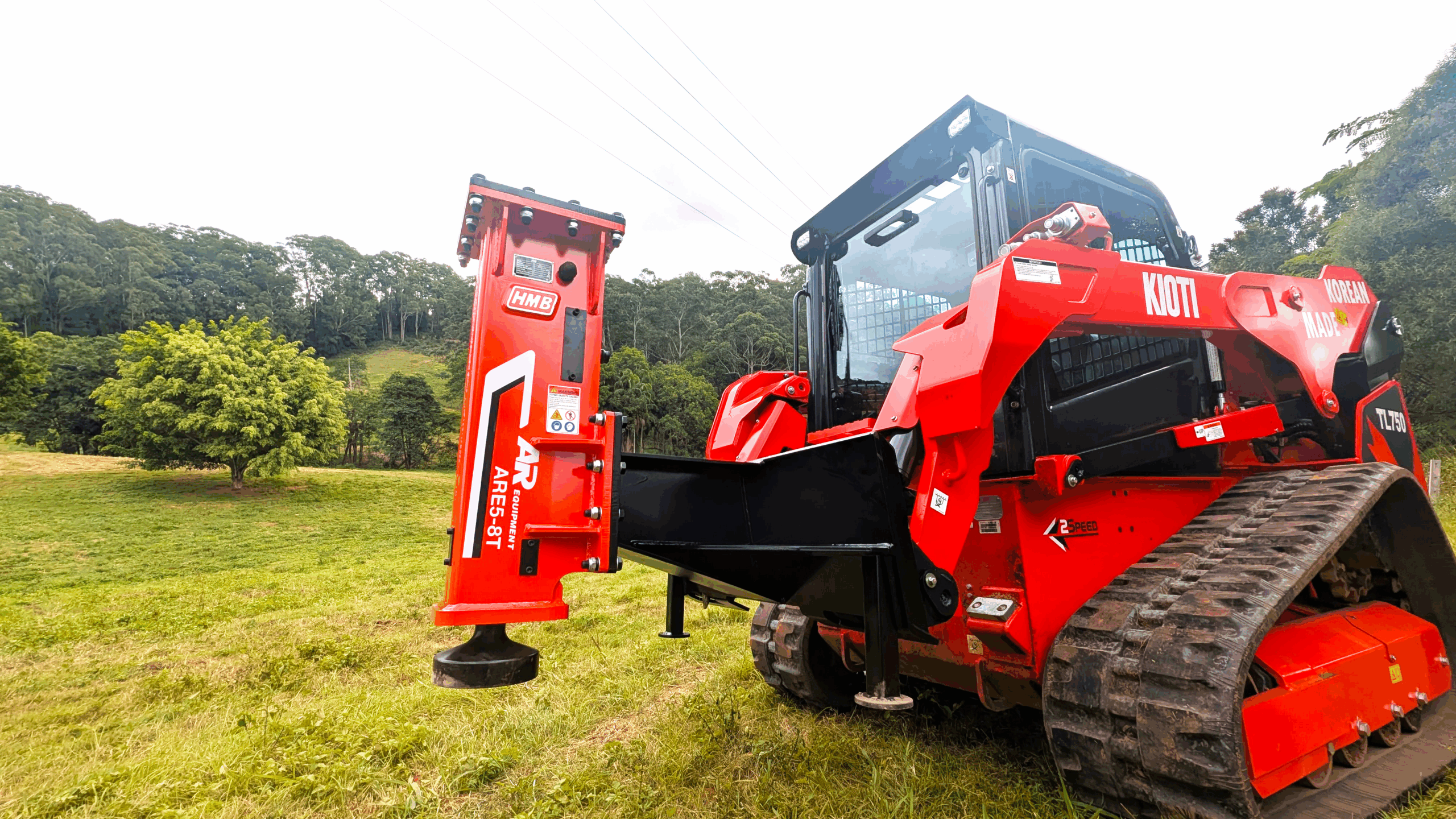

Hydraulic Hammer Attachments

Concrete slabs, rock formations, and compacted asphalt present formidable obstacles on Australian construction sites. Hydraulic hammer attachments solve these challenges with precision and power, earning their place among the most reliable excavator accessories available. These proven tools have been converting hydraulic energy into mechanical breaking force since 1967.

What is a Hydraulic Hammer Attachment

A hydraulic hammer attachment (also known as a hydraulic breaker) specialises in breaking hard materials, including concrete, asphalt, and rock. These robust implements deliver high-impact blows with exceptional precision, outperforming traditional manual hammers significantly.

The Australian market offers hydraulic hammers classified by mechanism and size. Operational designs fall into two categories: inner valve and outer valve configurations. Size classifications break down as follows:

- Mini hammers (400-1,200 pounds) – Suited for smaller indoor projects and confined spaces

- Medium hammers (1,900-3,700 pounds) – Perfect for concrete work and utility projects

- Large hammers (5,000-7,500 pounds) – Built for major demolition and excavation work

Each hydraulic hammer incorporates essential components: a cylinder that serves as the hydraulic system’s heart, a piston that converts kinetic energy into hammering energy, and a fully enclosed housing protecting internal parts while ensuring longevity. Many models include shock absorbers protecting the excavator from impact forces and steel bushings, minimising vibration.

How Hydraulic Hammer Attachments Work

The breaking process starts when your excavator’s hydraulic pump supplies pressurised fluid to the hammer through high-pressure hoses. This fluid enters the hammer’s valve system, which regulates flow to the piston with precision.

Breaking action occurs as pressurised fluid forces the piston to move rapidly within the hammer body. The system alternates between pressurising and depressurising chambers above and below the piston. The piston strikes the chisel or tool bit with tremendous force, transferring impact energy directly to the target material.

Following each impact, the valve system redirects fluid to create a pressure differential, returning the piston to its starting position for the next cycle. This rapid repetition allows the hammer to deliver multiple consistent blows per minute.

Best Use Cases for Hydraulic Hammer Attachments

Australian construction projects benefit from hydraulic hammers across multiple scenarios. Concrete demolition represents their primary strength – efficiently breaking up slabs, footings, foundations, and walls. Larger hammers handle major demolition projects, including bridge decks and multi-storey buildings.

These versatile attachments excel in:

- Trenching through rocky soil – Breaking through stratified rock layers

- Primary rock excavation – Where blasting isn’t permitted or practical

- Asphalt cutting and road maintenance – Essential for roadwork projects

- Foundation preparation – Breaking through hard surfaces for construction

- Mining and quarrying operations – Processing materials at source

The productivity gains are substantial. Hydraulic hammers reduce manual labour requirements significantly while enhancing jobsite safety through reduced noise levels compared to alternative breaking methods. Their durability and efficiency make them sound like a maximising long-term investment for Australian construction companies.

Important operational note: Experienced operators never hammer the same spot for more than 15 seconds, always position the hammer perpendicular to the working surface, and maintain consistent lubrication. These practices ensure maximum efficiency and extended service life.

Auger Attachments

Auger attachments excel at creating precise holes across diverse terrains and applications. These drilling specialists convert standard excavators into efficient boring machines, eliminating the time and labour costs associated with manual digging operations.

What is an Auger Attachment

An auger attachment is a drilling accessory designed to create clean, precise holes in materials ranging from soil and sand to rock and concrete. The attachment family splits into two distinct categories: drilling augers that remove material while boring, and anchor augers that operate with higher torque to drive helical piles while leaving soil in place for foundation work.

Most drilling augers function as post hole diggers, delivering straight, uniform holes with consistent results. Performance depends on two critical factors: your excavator’s hydraulic specifications and the soil composition you’re working with.

Key System Components:

- Drive Unit – Converts hydraulic power into rotational force

- Auger Bit – The drilling component is available in multiple sizes and configurations

- Hydraulic Hoses – Deliver is fluid to power the system

- Mounting System – Provides secure attachment and operational stability

Bit selection determines your success rate. Heavy-duty bits with cast teeth handle challenging conditions, while entry-level bits with bolt-on teeth suit simpler applications. Specialised bits tackle extreme conditions like solid rock drilling or precision tree planting.

How Auger Attachments Work

Auger attachments convert your excavator’s hydraulic pressure into rotational energy. Hydraulic fluid flows through hoses to the drive unit, pressurising internal gears that rotate the drill bit. This mechanical process generates powerful torque capable of cutting through resistant materials.

Most auger operations require a two-way auxiliary hydraulic system on your excavator. Machines lacking this feature may need modifications – consult equipment manufacturers before making changes to ensure compatibility and maintain warranty coverage.

Proper technique protects both equipment and operator safety. Keep the auger shaft perpendicular to the drilling surface to prevent bent shafts and costly repairs. Experienced operators avoid back-and-forth clearing movements, instead using smooth, single-direction jumps that reduce motor strain and extend service life.

Best Use Cases for Auger Attachments

Auger attachments deliver exceptional results across construction, landscaping, and agricultural applications:

Primary Applications:

- Fence post installation with uniform depth and alignment

- Tree and shrub planting holes in landscaping projects

- Foundation drilling for buildings and structures

- Utility pole installation with precise positioning

- Drainage system construction across varied terrain

The efficiency gains speak for themselves – drilling tasks that once required hours of manual labour are now completed in minutes. Interchangeable bits allow quick transitions between job requirements without equipment changes, maximising your operational flexibility.

Compact excavators with auger attachments prove particularly valuable in confined urban settings. These combinations access tight spaces where larger drilling equipment simply cannot operate, making them essential for projects in developed areas.

Safety advantages deserve recognition – operators remain protected in the excavator cab throughout drilling operations. This arrangement eliminates risks associated with manual digging, including cave-ins and tool-related injuries.

Note: Match auger specifications with your excavator’s capabilities, select appropriate bit types for soil conditions, and evaluate mounting systems for compatibility before making your investment decision.

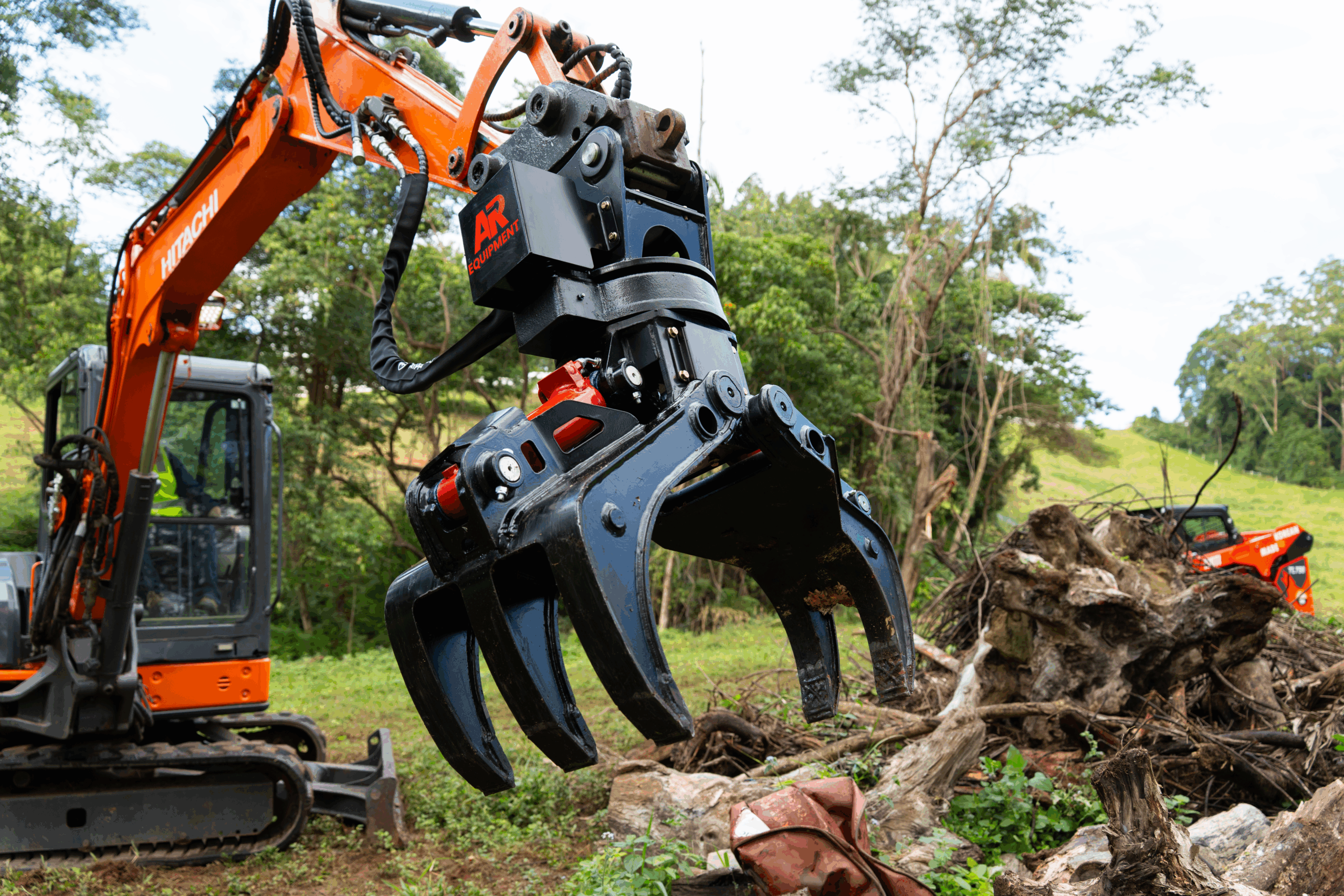

Grapple Attachments

Grapple attachments solve a common excavator limitation: securely handling irregularly shaped materials. These hydraulic-powered tools turn your standard excavator into a material handling specialist, enabling you to grab and manipulate objects that would otherwise demand significant manual labour.

What is a Grapple Attachment

A grapple attachment is a specialised tool that grasps and holds large or awkwardly shaped objects, including rocks, logs, demolition debris, and other bulky materials. These attachments mount directly to your excavator arm and rely on the machine’s hydraulic system for operation. Quality grapples feature robust steel construction with hydraulic arms or jaws that open and close precisely to secure different materials.

The grapple family includes several distinct types, each built for specific applications:

- Demolition and sorting grapples – Heavy-duty attachments purpose-built for demolishing structures and managing construction debris

- Bunching grapples – Single cylinder designs with bypassing jaws and large gripping areas, perfect for loading short logs

- Log grapples – Strong, dual cylinder models with 2×1 finger bypassing jaws, ideal for handling single large logs or smaller bundles

- Multi-purpose grapples – Versatile options that handle various materials across different applications

- Contractor’s grapples – Feature a stationary jaw with an upper jaw that moves off the bucket cylinder, excellent for sorting operations

Fixed versus rotation models represent another key distinction. Rotation models include a hydraulic rotator that allows the attachment to swivel independently, giving you greater flexibility when positioning materials.

How Grapple Attachments Work

Grapple attachments operate through hydraulic power systems. Hydraulic grabs use your excavator’s auxiliary hydraulic circuit to open and close the grapple jaws, providing precise control during material handling. Mechanical grabs, by contrast, utilise the bucket cylinder for opening and closing functions.

The grapple’s design enables significant tooth overlap, effectively compressing loads while allowing smaller rocks and dirt to fall through. This feature proves particularly valuable when sorting materials or performing cleanup operations.

Rotation models include a hydraulic rotator that enables the attachment to swivel independently of the excavator’s arm. This flexibility makes them ideal for jobs requiring precise material placement without repositioning the entire machine. However, they typically need two separate auxiliary hydraulic functions, which can limit options since many machines come with only one hydraulic circuit from the factory.

Best Use Cases for Grapple Attachments

Grapple attachments excel across multiple industries, making them essential tools for specific applications.

Construction and demolition projects benefit from grapples’ ability to efficiently remove and sort debris while grasping irregularly shaped objects. Their robust construction handles heavy concrete, metal, and other construction waste without difficulty.

Forestry and logging operations rely on grapples to securely hold logs and timber, enabling efficient loading, unloading, and stacking. Their specialised arms and gripping mechanisms make them indispensable for managing tree logs, branches, and vegetation during land clearing projects.

Recycling facilities depend on excavator grapples to handle materials like scrap metal, plastics, and other recyclables. Their durability allows safe management of sharp or irregularly shaped objects, supporting sustainable waste management practices.

The key advantages include enhanced material handling efficiency, precise control when moving objects, reduced manual labour requirements, and versatility across multiple applications. Their ability to securely grasp materials of various shapes and sizes makes them valuable additions to any Australian excavator fleet.

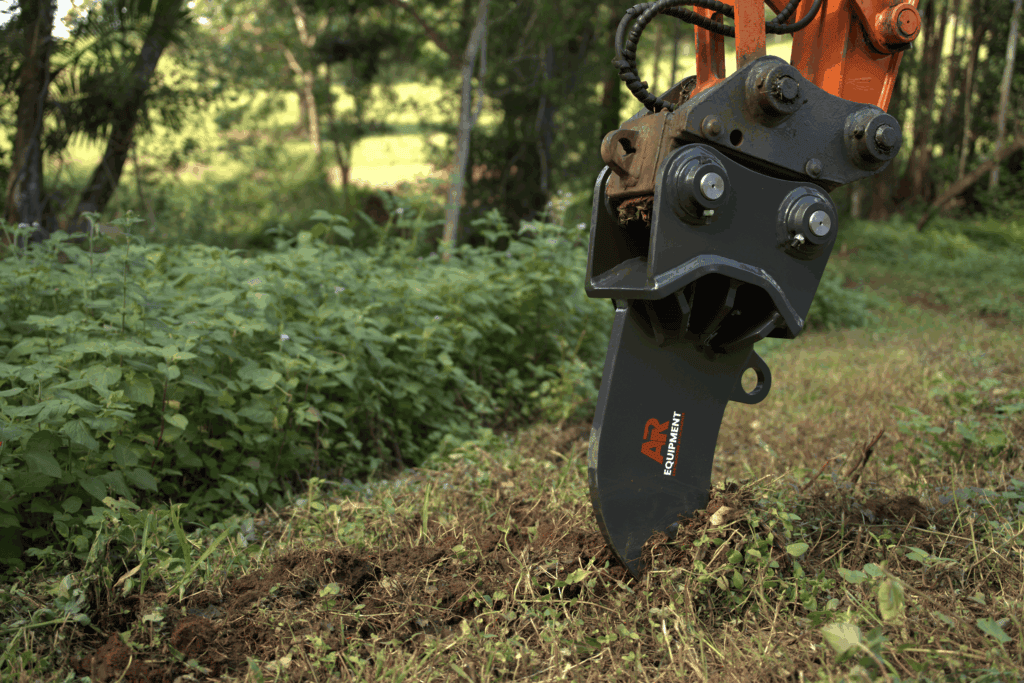

Ripper Attachments

Ripper attachments solve one of construction’s most persistent challenges: breaking through materials that resist conventional digging equipment. These specialised tools concentrate your excavator’s full power through a single, hardened point—making quick work of ground conditions that would otherwise slow your project to a crawl.

What is a Ripper Attachment

A ripper attachment features a robust, pointed tooth designed to concentrate force and break up challenging materials like hardpan soil, rock layers, and frozen ground. The implement consists of a heavy-duty shank topped with a replaceable hardened steel tip, engineered specifically to penetrate resistant surfaces that would damage standard buckets.

The ripper’s streamlined design cuts through materials rather than simply pushing them aside. Most quality rippers use high-strength steel construction with reinforced joints capable of handling extreme operational stress. Advanced models often include shock absorbers that protect your excavator from dynamic loads during heavy breaking work.

This focused approach makes rippers remarkably effective where conventional attachments fail. The single-point design channels your machine’s entire hydraulic power through one concentrated area, delivering penetrating force that standard buckets simply cannot match.

How Ripper Attachments Work

Ripper attachments operate by concentrating your excavator’s power through the narrow tip of the hardened tooth. This concentration creates tremendous force at a small contact point, enabling the ripper to penetrate and fracture compacted materials that resist broader digging tools.

The tooth’s curved design provides a mechanical advantage during operation. As your excavator applies downward force, the ripper’s shank acts as a lever, helping to pry materials loose once the initial penetration occurs. This combination of penetration and leverage delivers efficient breaking action across tough ground conditions.

Proper technique involves positioning the ripper tooth perpendicular to the working surface and applying steady pressure. The tooth gradually loosens material through controlled movements, preparing difficult areas for follow-up excavation with your standard bucket.

Best Use Cases for Ripper Attachments

Ripper attachments excel in challenging scenarios where standard equipment struggles:

Breaking compacted ground – Rippers penetrate frozen soil, rock layers, and heavily compacted earth, preparing surfaces for efficient excavation with your regular bucket.

Tree stump removal – The sharp tooth cuts through root systems while the curved design provides leverage to extract stubborn stumps from the ground.

Concrete and asphalt breaking – Rippers efficiently fracture hard surfaces without subjecting your primary digging equipment to excessive wear and potential damage.

The real value lies in protection and efficiency. Rather than forcing your expensive digging bucket through materials that could damage its cutting edge, you use the ripper to break up tough sections first. This approach reduces wear on your primary attachments while speeding up overall project completion.

Smart contractors recognise that ripper attachments pay for themselves by extending the service life of other equipment and reducing project delays caused by challenging ground conditions.

Thumb Attachments

Thumb attachments offer one of the most practical solutions for enhancing your excavator’s gripping capabilities without the expense of dedicated grapple systems. These clever accessories work alongside your existing bucket, creating an opposing force that enables secure handling of irregularly shaped materials across diverse applications.

What is a Thumb Attachment

A thumb attachment functions as a claw-like lever that pairs with your excavator’s bucket to create a powerful gripping system. Think of it as giving your excavator the equivalent of an opposable thumb – the attachment mimics this human functionality by providing the opposing force needed to securely grasp objects that would otherwise slip from a standard bucket.

This design approach delivers remarkable value through its simplicity. Rather than requiring expensive grapple attachments, the thumb works with your existing bucket to handle materials that would normally demand manual labour or specialised equipment. The thumb stores neatly in an upright position when not needed, allowing standard digging operations to continue without interference.

The straightforward design, combined with lower costs compared to dedicated grapples, explains why many excavator manufacturers now include thumb mounting plates as standard equipment on new machines.

How Thumb Attachments Work

Thumb attachments operate through either hydraulic or mechanical systems, with hydraulic versions being the more common choice. Most hydraulic thumbs install as main pin configurations, using the excavator’s existing bucket pin as the pivot point – this setup minimises installation complexity while ensuring reliable operation.

The hydraulic system connects a cylinder between the thumb and a base plate welded to the machine’s stick. This arrangement gives operators the flexibility to adjust grip strength and positioning based on the specific task at hand. Operators can work at various distances from the machine while maintaining precise control over the gripping action.

Mechanical thumbs offer a simpler alternative, remaining in fixed positions and relying on bucket rotation to create the necessary gripping pressure. While less flexible than hydraulic versions, they provide reliable performance for basic applications.

Best Use Cases for Thumb Attachments

The versatility of thumb attachments makes them valuable across multiple Australian construction scenarios:

- Land clearing projects – efficiently moving brush, fallen trees, and vegetation debris

- Demolition operations – securing and removing concrete chunks, building materials, and structural debris

- Stump removal work – particularly effective when used with specialised stump pullers for root system extraction

- Landscaping tasks – handling rocks, large branches, and awkward materials that resist standard bucket work

What sets thumb attachments apart from other specialised tools is their ability to enhance multiple operations without limiting your excavator’s primary functions. The thumb doesn’t replace your bucket – it makes your bucket significantly more capable while preserving all normal digging operations.

This multi-purpose approach delivers excellent value for contractors who need enhanced material handling without the expense of multiple specialised attachments.

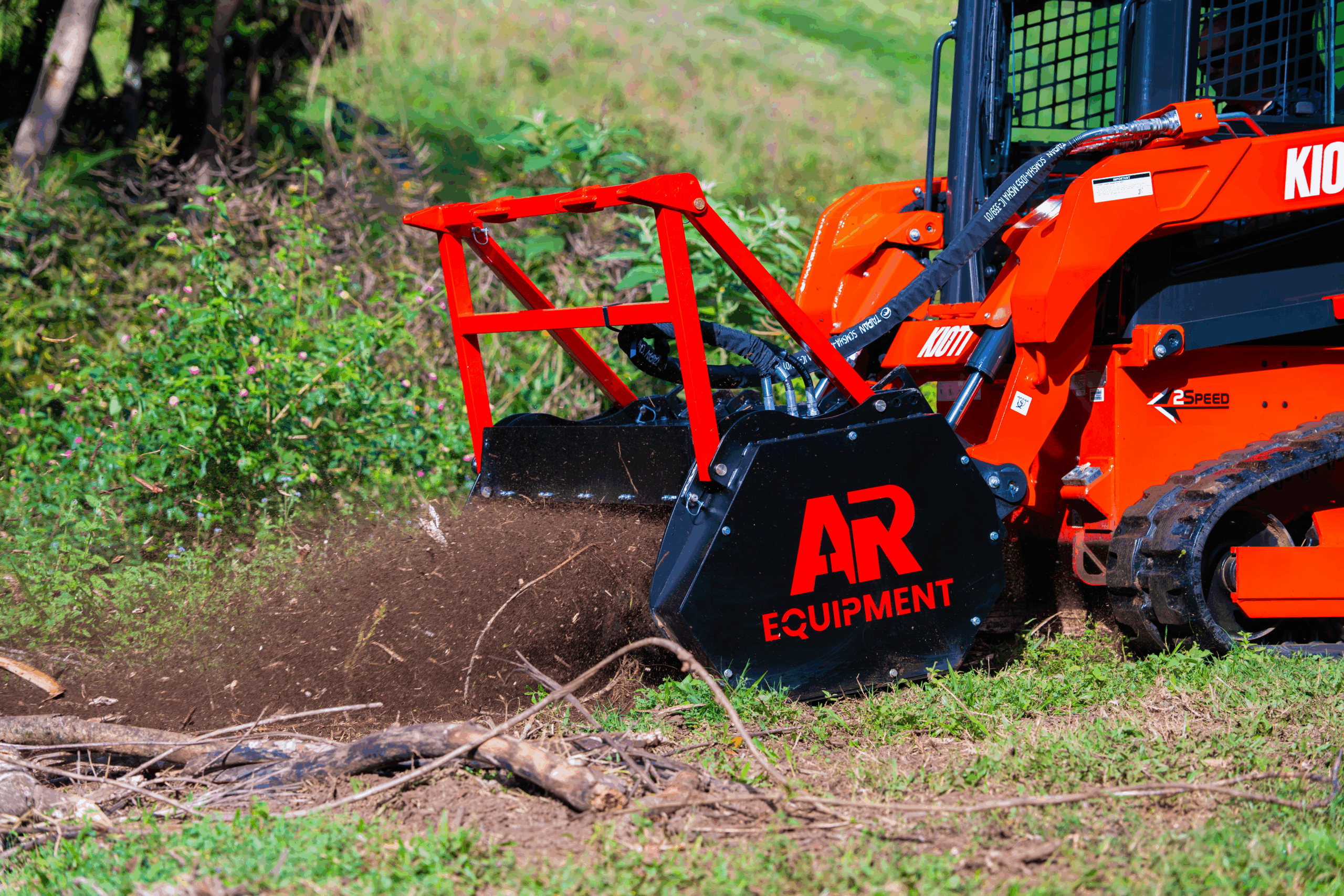

Crusher Attachments

Material recycling directly on-site has become a game-changer for Australian contractors seeking to reduce project costs and disposal fees. Crusher attachments enable excavator operators to process demolition waste and hard materials without the expense of transporting debris off-site.

What is a Crusher Attachment

A crusher attachment functions as a compact jaw crusher mounted directly onto your excavator, creating a mobile crushing solution for construction sites. This specialised tool crushes construction debris, rubble, masonry, asphalt, natural stones, and rocks exactly where you need them processed.

The design features a bucket configuration with a fixed bottom jaw paired with one moving jaw that work together to break down materials. This setup gives you the crushing power you need while maintaining the mobility and versatility of your excavator.

Essential components include:

- Hydraulic motor and valve system regulating oil flow and pressure

- Fixed and movable jaws with adjustable gap settings

- Self-loading capability for material charging and discharging

- Eccentric element mounted on an axle controlling jaw movement

Jaw sizes typically range from 970mm to 1650mm, directly determining the final size of your processed materials.

How Crusher Attachments Work

The operation centres on your excavator’s hydraulic system. Hydraulic hoses connect directly to the attachment for intake and drainage, while a hydraulic valve block manages the correct oil flow and pressure to power the movable jaw.

Positioning matters during operation—the excavator places the crusher bucket vertically, allowing crushed materials to fall through the bottom naturally. Materials enter from the top, passing between the two jaws where the moving jaw crushes them against the fixed jaw. Processed material then falls through the gap between the specialised jaws.

An eccentric element rotated by the hydraulic motor creates the crushing action needed to break down tough materials effectively. This simple but robust mechanism handles demanding processing tasks reliably.

Best Use Cases for Crusher Attachments

These attachments deliver exceptional value in several key scenarios:

- Demolition projects – reducing concrete and brick debris to manageable, reusable sizes

- Road construction and excavation – processing materials for immediate reuse as base material

- Environmental reclamation – recycling accumulated waste materials on-site

- Quarry operations – crushing rocks and stones at the extraction point

The major advantage lies in eliminating transportation and disposal costs by processing materials where they’re generated. Crushed materials become immediately available as backfill, road base, or other construction applications—essentially creating a closed-loop recycling system right on your jobsite.

For Australian businesses managing tight project budgets, this capability represents significant cost savings while supporting sustainable construction practices.

Quick Hitch Attachments

Quick hitch attachments serve as the backbone of efficient excavator operations, acting as connectors that enable rapid tool changes across your workday. While other attachments handle specific tasks, quick hitches focus purely on operational efficiency—eliminating the time-consuming process of manual attachment changes.

What is a Quick Hitch Attachment

A quick hitch attachment functions as a connector system fitted to excavator arms, allowing buckets and other attachments to be swapped quickly without leaving the operator’s cabin. This device can save substantial time during operations, particularly on jobs requiring frequent tool changes.

The market offers several quick hitch configurations to suit different operational needs:

- Manual hitches – Require physical pin insertion through attachment holes

- Mechanical hitches – Use over-centre levers or screw threads for securing

- Semi-automatic systems – Engage through hydraulic power, but still need manual safety pin insertion

- Fully automatic systems – Operate completely from the cabin with no manual handling required

Quality quick hitches incorporate dual safety mechanisms: a primary retaining system plus a backup safety system that prevents accidental detachment during operation.

How Quick Hitch Attachments Work

Quick hitches function through locking systems that secure attachments to the excavator arm via either manual pins or automatic hydraulic pressure mechanisms. The device mounts directly to the excavator’s dipper arm, featuring mounting points that align precisely with attachment pins.

Essential components include a mounting frame connecting to the excavator arm, a locking mechanism (mechanical or hydraulic) that secures attachments, and safety catches preventing accidental release. These systems rely on positive hydraulic pressure and secure mechanical connections to maintain safe attachment during operation.

The effectiveness of quick hitches depends largely on proper alignment and secure engagement of all safety mechanisms before commencing work.

Best Use Cases for Quick Hitch Attachments

Quick hitches prove most valuable on dynamic jobsites requiring frequent attachment changes. Construction projects benefit significantly from rapid switching between buckets, hammers, and grapples throughout the workday. Demolition work particularly benefits from quick exchanges between pulverisers, shears, and handling attachments.

The safety advantages deserve recognition—quick hitches reduce manual handling of heavy attachments, minimising injury risks for operators and ground crews. They also increase equipment versatility, allowing single excavators to handle multiple task types with appropriate tools.

This adaptability makes excavators more valuable assets on Australian construction sites, where project requirements can change rapidly and equipment versatility directly impacts profitability.

Comparison Table

Making the right attachment choice becomes simpler when you can see the key differences side-by-side. This comparison breaks down the eight essential attachment types, highlighting their core functions and practical applications for Australian contractors.

| Attachment Type | Primary Function | Key Components | Operation Method | Main Applications |

| Bucket | Material digging and handling | Container body, cutting edge, teeth (on some models) | Direct connection to the excavator arm, controlled by the hydraulic system | General excavation, trenching, grading, and material handling |

| Hydraulic Hammer | Breaking hard materials | Cylinder, piston, enclosed housing, shock absorbers | Converts hydraulic pressure to mechanical impact force | Concrete demolition, rock breaking, asphalt cutting, and foundation work |

| Auger | Drilling precise holes | Drive unit, auger bit, hydraulic hoses, mounting system | Converts hydraulic pressure to rotational force | Fence post installation, tree planting, foundation holes, utility pole installation |

| Grapple | Grasping and holding materials | Hydraulic arms/jaws, rotation mechanism (on some models) | Hydraulic-powered opening/closing of jaws | Demolition debris handling, log handling, recycling operations |

| Ripper | Breaking tough ground | Heavy-duty shank, hardened steel tip, reinforced joints | Concentrates force through a single point | Breaking frozen ground, tree stump removal, and rock breaking |

| Thumb | Creating an opposing grip with the bucket | Pivot point, hydraulic cylinder, base plate | Works with the bucket to create the pinching action | Land clearing, demolition waste handling, stump removal |

| Crusher | On-site material processing | Fixed jaw, movable jaw, hydraulic motor, valve system | Crushes material between moving and fixed jaws | Demolition waste processing, rock crushing, on-site recycling |

| Quick Hitch | Rapid attachment switching | Mounting frame, locking mechanism, safety catches | Manual or hydraulic locking systems | All applications requiring frequent attachment changes |

Each attachment serves distinct purposes, yet many complement each other on complex projects. The most successful contractors often combine multiple attachments – using rippers to break tough ground before switching to buckets for excavation, or pairing thumbs with buckets for material handling tasks.

Conclusion

Excavator attachments turn your machine into a multi-functional powerhouse that handles diverse construction challenges with precision and efficiency. The right attachment makes the difference between struggling through tasks and completing them efficiently—whether you need buckets for material handling, hydraulic hammers for concrete demolition, or augers for precise drilling operations.

These specialised tools deliver substantial value beyond their initial cost. Grapples and thumbs enable secure handling of irregular materials, while rippers tackle the toughest ground conditions that would otherwise slow your progress. Crusher attachments create immediate material recycling opportunities, eliminating transportation costs and disposal fees. Quick hitch systems multiply these benefits by allowing rapid tool changes without leaving the operator cab.

The investment in quality attachments pays dividends through increased productivity, reduced manual labour requirements, and enhanced jobsite safety. Rather than purchasing multiple specialised machines, the right combination of attachments transforms a single excavator into a versatile solution for almost any construction scenario.

If you’re looking for expert advice on selecting the right excavator attachment for your project, reach out to AR Equipment for professional services and guidance. Their team can help you determine the most efficient attachment solutions for your specific plumbing and excavation needs.

Smart attachment selection maximises your equipment investment while positioning your operation to handle diverse projects with confidence and efficiency.

Key Takeaways

Understanding excavator attachments transforms your machine from a basic digger into a versatile construction powerhouse capable of handling diverse jobsite challenges.

• Choose the right bucket type for your material – General-purpose buckets handle everyday tasks, while specialised options like rock buckets and grading buckets optimise performance for specific conditions.

• Hydraulic hammers excel at breaking tough materials – These powerful attachments convert hydraulic energy into mechanical force, making them essential for concrete demolition and rock breaking.

• Auger attachments create precise holes efficiently – Perfect for fence posts, tree planting, and foundation work, they dramatically reduce manual digging time and labour costs.

• Grapple and thumb attachments enhance material handling – These tools enable secure gripping of irregularly shaped objects like logs, debris, and rocks that standard buckets cannot handle effectively.

• Quick hitch systems maximise productivity – By enabling rapid attachment changes without leaving the cab, they eliminate downtime and allow operators to switch between tasks seamlessly.

The key to maximising your excavator’s potential lies in matching the right attachment to each specific task. With proper selection, a single excavator can replace multiple specialised machines, delivering significant cost savings and operational efficiency across construction, demolition, and landscaping projects.

FAQs

What are the most common types of excavator attachments? The most common excavator attachments include buckets for digging and material handling, hydraulic hammers for breaking hard materials, augers for drilling holes, grapples for gripping irregularly shaped objects, and quick hitches for rapidly switching between attachments.

How do hydraulic hammer attachments work? Hydraulic hammer attachments convert hydraulic pressure from the excavator into mechanical impact force. The pressurised fluid moves a piston that strikes a chisel or tool bit, delivering powerful blows to break concrete, rock, or other hard materials.

What are the advantages of using a quick hitch attachment? Quick-hitch attachments enable operators to switch between different tools quickly without leaving the cab. This saves significant time on job sites, increases productivity, reduces manual handling risks, and allows excavators to perform a wider range of tasks efficiently.

How do grapple attachments enhance an excavator’s capabilities? Grapple attachments enable excavators to securely grasp and manipulate irregularly shaped materials like logs, debris, and large rocks. They excel in demolition, forestry, and recycling operations by providing a firm grip on objects that standard buckets cannot handle effectively.

What factors should be considered when choosing excavator attachments? When selecting excavator attachments, consider the specific tasks you’ll be performing, the materials you’ll be working with, your excavator’s specifications and hydraulic capabilities, jobsite conditions, and the frequency of use for each attachment. Matching the right attachment to each task maximises efficiency and productivity.